Description

The Kalundborg Industrial Symbiosis Association exists since 1972 and interlinks thirteen private and public companies. The local industrial sector includes petrochemical, light building construction material, food, pharma, biotech, energy and bioenergy as well as waste processing.

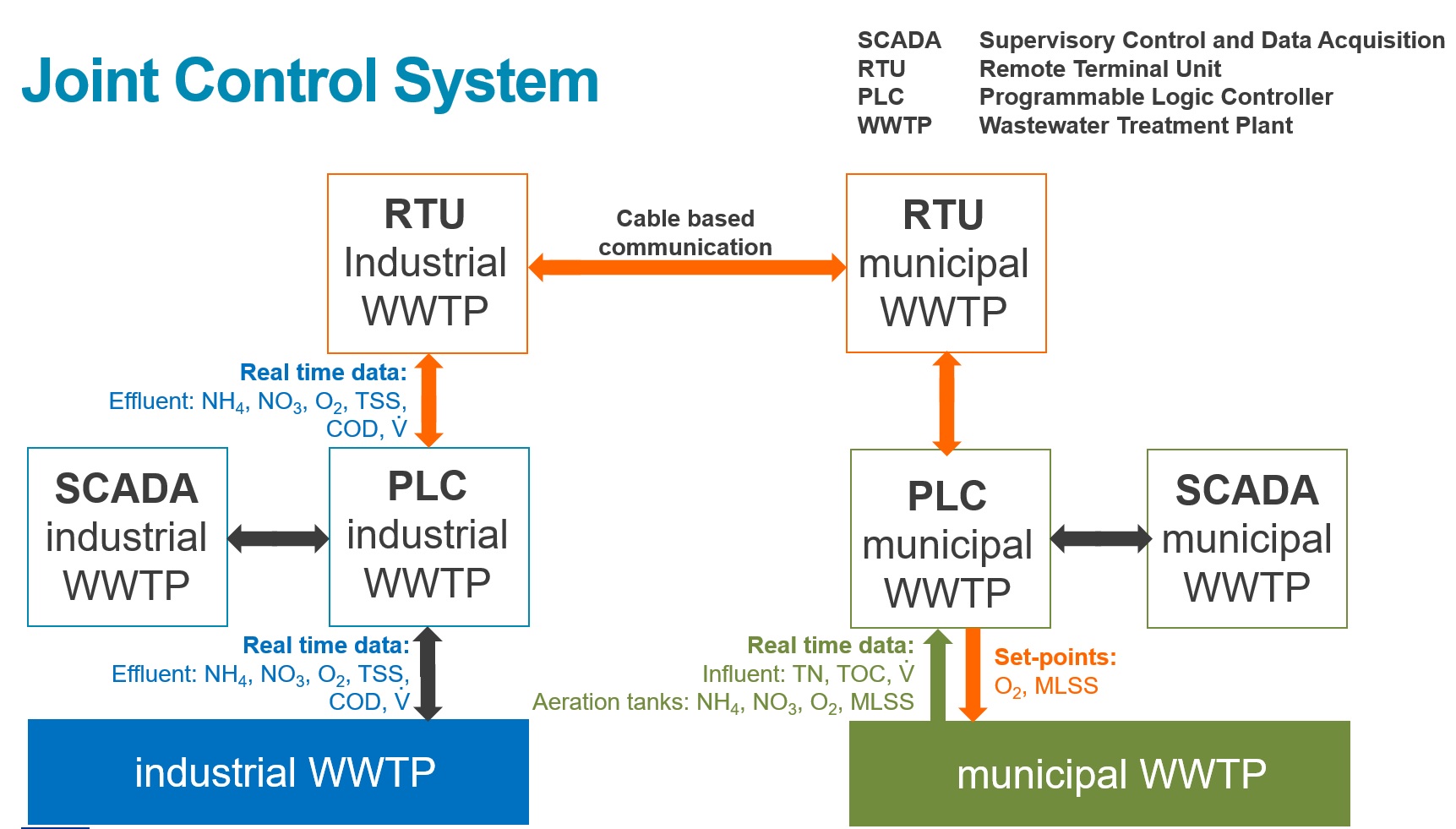

Different circular economy approaches for water, energy and materials are already implemented, e.g. the reuse of cooling water for steam production, the reuse of gypsum from exhaust gas cleaning to produce plasterboards, integrated heat management and the transfer between the industries and the district heating network as well as heat recovery from process water for district heating. Even though, the Kalundborg Industrial Symbiosis already recovers and reuses certain materials, water and energy, there are still options to intensify and extend the circular economy related strategies. One aspect is the treatment of wastewaters which is done by two companies Novozymes and Kalundborg Utility.

Ultimate focuses on the optimisation of two WWTPs aiming at developing and implementing a joint control system for both plants, the recovery of the WWTP effluent as fit-for-purpose water and to explore the potential for the recovery of valuable compounds from the industrial wastewater as well as on identifying options to reuse thermal energy recovered from wastewater. Therefore, the symbiotic relationship between Novozymes and Kalundborg Forsyning is extended in the frame of Ultimate to create a win-win situation for both.

Applied technologies

Technology performance and best practices

Water reclamation

In Kalundborg (DK), ULTIMATE successfully produced high quality water for the use as industrial cooling water. The point of application was the effluent from the municipal wastewater treatment plant (mWWTP), which receives both municipal wastewater and biotechnological/pharmaceutical wastewater. This composition was quite challenging as it contained high levels of non-degradable organic fractions from the industrial wastewater and a high potential for fouling processes was expected. Therefore, different pre-treatments for a reverse osmosis were tested: conventional ultrafiltration (150 kDa), a novel ultra-tight ultrafiltration (4 kDa) and an open nanofiltration (1 kDa). A dual-media filter was installed upstream of the ultrafiltration to retain particulate loads that were sometimes discharged from the mWWTP's secondary clarifier. The pilot study showed that the combination of a dual media filter with a pre-filter, conventional ultrafiltration and reverse osmosis was suitable for this wastewater composition. Plans for a possible large-scale implementation in Kalundborg are under development.

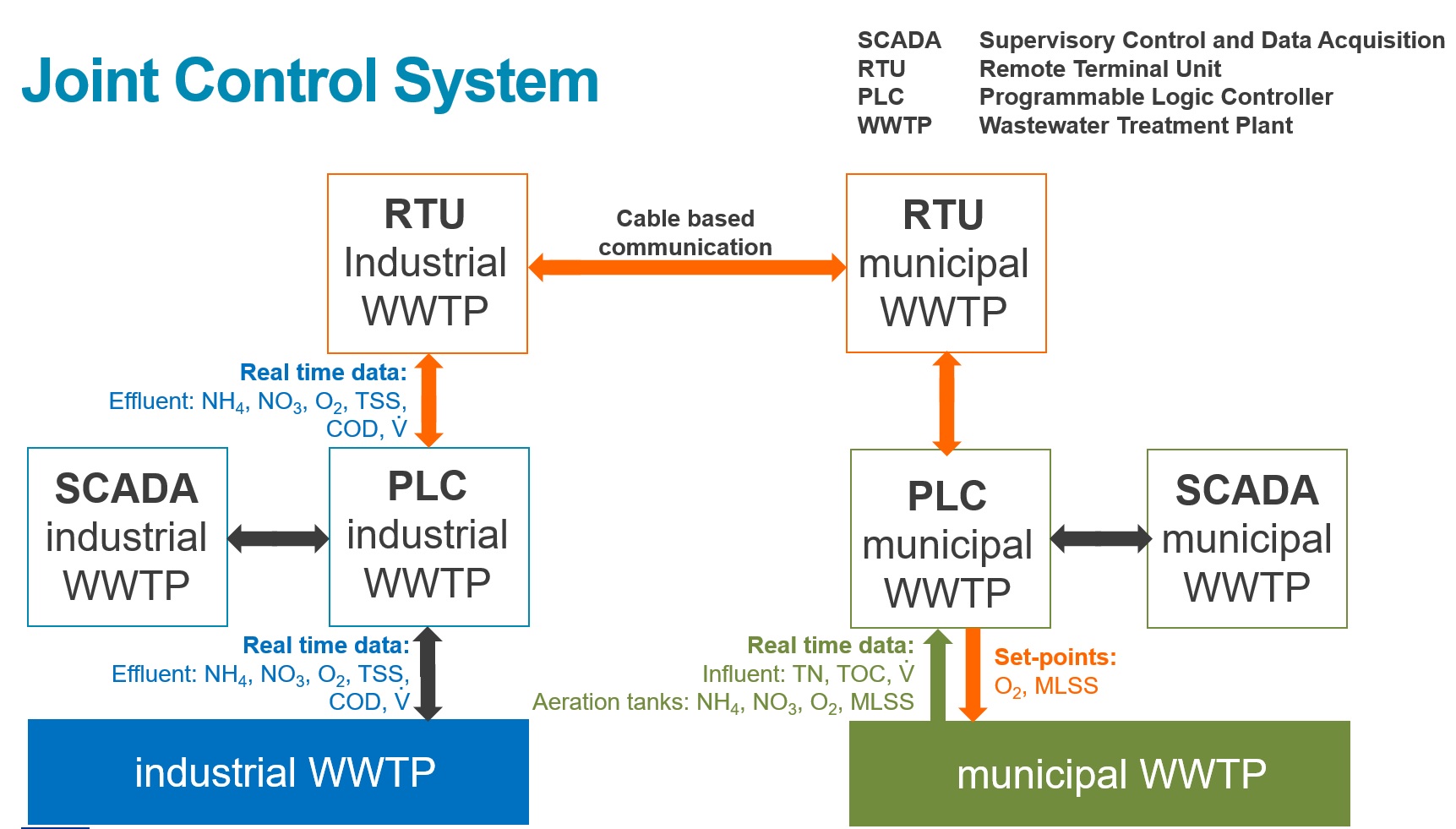

Joint control system

In addition, a joint control system was implemented at two interconnected WWTPs. There, an industrial WWTP pre-treats wastewater from the biotech sector, before it enters the mWWTP, where the industrial wastewater is mixed with municipal wastewater for further treatment. The joint control system was designed to provide early warnings of nitrogen shock loads from the iWWTP. This allowed the aeration system at the mWWTP to be operated based on the actual aeration demand and prevented over-aeration. In three months of operation, the demand driven aeration increased the energy efficiency of the entire plant, resulting in a 15% reduction in its energy consumption. This increase in energy efficiency still needs to be validated over a longer period of operation and also with actual nitrogen shock loads from the industrial WWTP.

Outcome of assessments

Life cycle assessment

Water recycling and seawater desalination can reduce freshwater extraction from Lake Tissø and thus reduce local water stress. Water recovery is associated with a higher energy demand and a higher carbon footprint when the recovered water replaces fresh water from Lake Tissø, while it is associated with a lower energy demand and carbon footprint when the recovered water replaces that from seawater desalination. Of all pre-treatment membranes, conventional UF had the lowest carbon footprint and highest yield and was therefore the preferred option. In a large-scale plant, the yield and thus the wastewater production is of importance due to the hydraulic limitation of the secondary treatment.

Total cost of ownership (TCO)

The TCO assesses the treatment of wastewater (with a starting capacity at 2 M m3/year) in Kalundborg comparing four scenarios combining coagulation, sand filtration, and reverse osmosis (RO) with varying filtration technologies: conventional UF (cUF), cUF with UV treatment, ultra-tight UF (utUF), and open nanofiltration (oNF). Over a 30-year evaluation period, TCO ranges from 140 to 150 million EUR, with capital costs and operational costs, in particular electricity cost, as the major cost item. A sensitivity analysis on electricity prices (ranging from 0.121 to 0.134 EUR/kWh) shows a 1-3% variation in TCO across the 4 scenarios, suggesting minor annual fluctuation, however for long-term financial planning and risk management, electricity pricing should be considered. Novel filtration technologies (utUF and oNF) have higher energy demands, increasing their TCO compared to cUF and cUF-UV, which underscores the need for careful energy management to maintain financial sustainability.

Quantitative microbial risk assessment

The quantitative microbial risk resulting from water reuse in cooling towers as well as for street cleaning and car washing was assessed for different pre-treatment options. The risk assessment indicated that the risk of introducing relevant concentrations of Legionella into the cooling tower system is negligible if a double membrane system (UF/RO or NF/RO) is applied. For the purpose of street cleaning and car washing the microbial water quality is considered acceptable, even if only a UF or NF treatment is applied. The additional RO unit does not seem necessary for this kind of reuse. The use of secondary effluent is not recommended.

Concept study for material recovery from industrial wastewater

A concept study was carried out on the recovery of valuable compounds from industrial wastewater resulting from the production of enzymes, insulin and pharmaceutical proteins. It was concluded that by reducing the overall water consumption through hybrid membrane systems in the industrial production lines, water is generated for reuse within the industry. This system also produces concentrates with high nutrient, salt and protein content, which are ideal streams for material recovery. Overall, a high recovery potential was found for phosphate and sulphate as apatite, gypsum or syngenite. However, the recovery of proteins appears to be less favourable. In order to scale up the system, laboratory and pilot tests are recommended to confirm the expected recovery potential.

Legislation and policy recommendations

Clarifying responsibilities and developing consistent guidelines for water reuse licensing and service provision across the EU are essential to ensure effective practices. The strategic agenda proposes comprehensive coverage of all water reuse types, emphasizing safety, environmental impact assessment, and the integration of reclaimed water into local water balances based on regional circumstances. Future regulations should establish minimum standards for non-agricultural uses, enhance risk assessment, and promote research on innovative water reuse technologies and practices. (see also D1.10)

Applied products

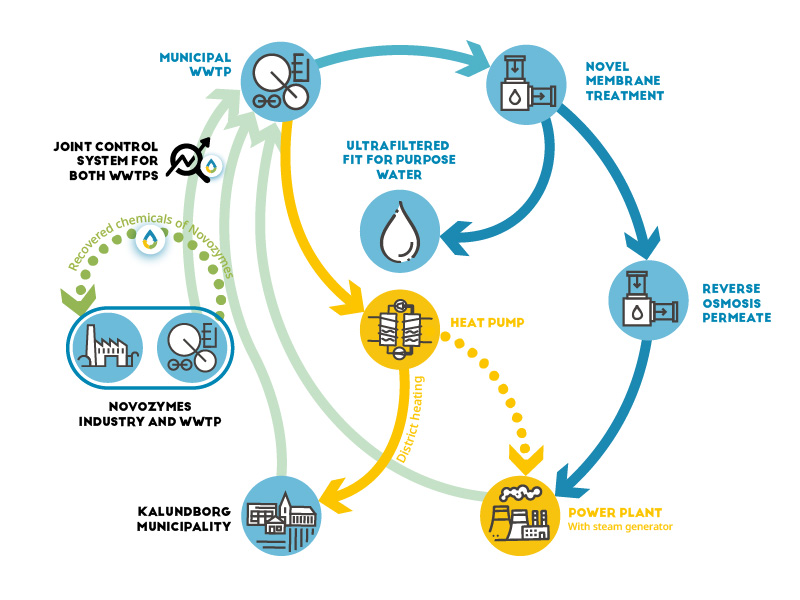

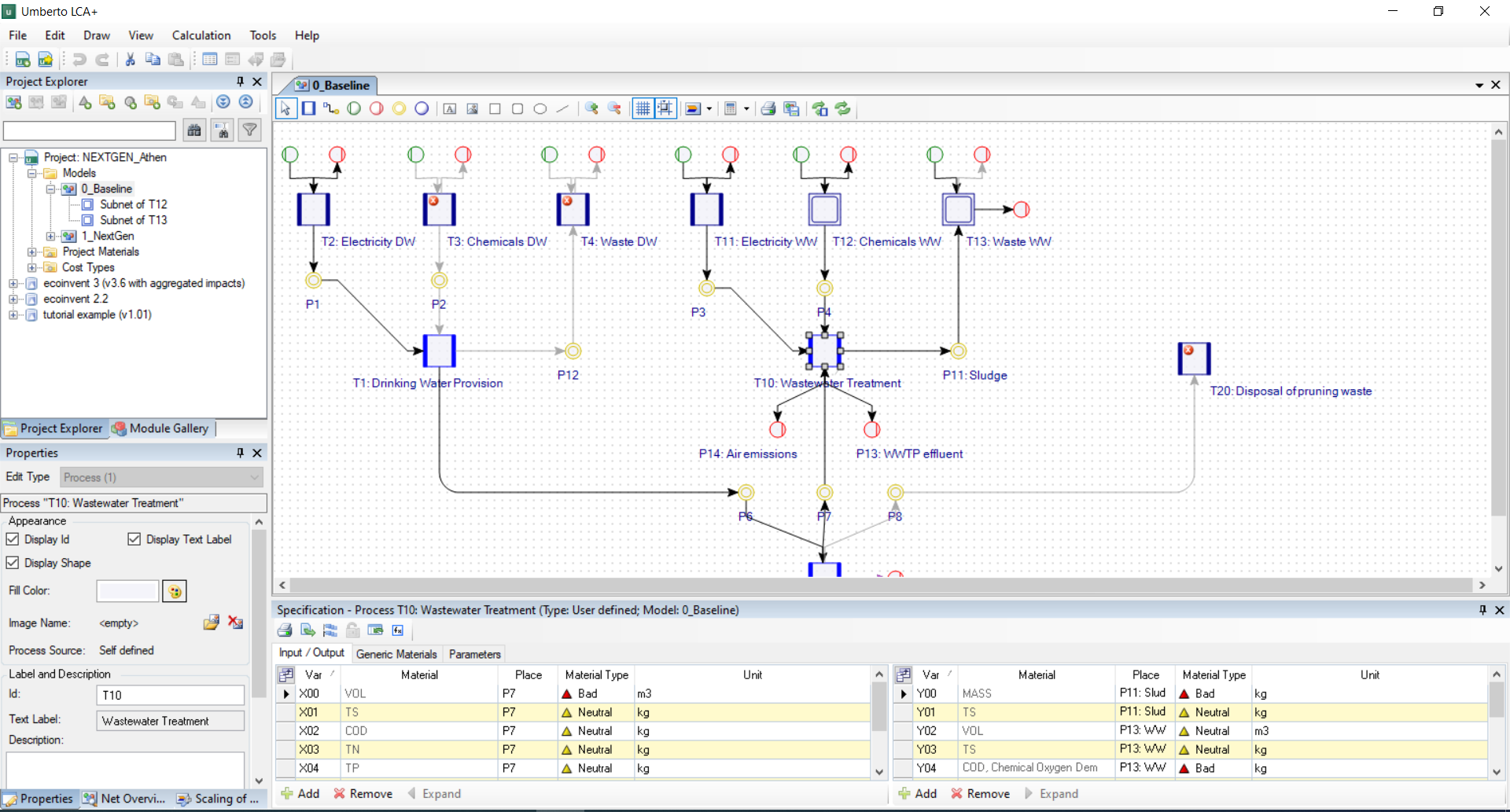

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…

ULTIMATE QMRA tool

To facilitate the design and assessment of treatment trains for water reuse, KWB is supporting the development of an op…