Description

IVAR Sentralrenseanlegg Nord-Jæren WWTP (SNJ) receives wastewater from over 300,000 inhabitants in Rogaland County, at the south-west coast of Norway. The plant was built in 1992 as a chemical treatment plant and was expanded and converted to a mechanical-biological plant in 2018. The new plant was designed with a focus on resource recovery, including both energy and nutrient recovery, and utilization of digestate as a commercial fertilizer product.

SNJ is designed with primary filtration at 100 µm, and biological treatment with enhanced biological Phosphorous Removal (EBPR) for removal of organic load and phosphorous. Sludge treatment consists of anaerobic digestion, dewatering and drying of the digestate. The dried digested sludge, consisting of 2/3 wastewater sludge and 1/3 external sludge (food waste, aquaculture waste products, diary waste etc.), is then used to produce a mineral-organic fertilizer. All sludge treatment is carried out on-site, and the energy required for heating digesters and drying the sludge is in large supplied from the biogas produced.

The development and production of fertilizer from dried digestate at IVAR SNJ has been carried out in cooperation with Grønn Vekst/TerraMarine[1] as a commercial partner. As of 2022, a total of approx. 4000 tons of fertilizer pellets were produced and exported. A portion of the biogas produced in the anaerobic digesters is utilized at the plant, while the rest of the bio-methane is sold and distributed to external consumers by IVARs commercial partner Lyse Neo. In 2022 the plant produced an amount of biomethane corresponding to 20 GWh of energy.

Since 2020, IVAR SNJ has participated in the Wider Uptake project as a case study. The main objectives at SNJ within Wider Uptake have been increasing energy and resource recovery in addition to resource utilization and commercialization of fertilizer and biogas.

The following activities has been carried out within the project:

- Investigation of the possibility for increasing sludge removal in primary treatment to maximize energy recovery.

- Improving performance of biological treatment to increase biological phosphorous removal (full scale and pilot testing).

- Pilot testing of different technologies for P-recovery as struvite

Technology performance and best practices

- Primary filtration at SNJ, IVAR – Investigation of possibilities for higher SS recovery

Primary treatment at SNJ WWTP consists of 20 Hydrotech drum filters with sieve pore size of 100 µm. The primary filtration readily separates at least 50 % of the suspended solids (SS) from the wastewater without addition of coagulants or flocculants. By increasing the SS removal, it is possible to increase the overall sludge production at the plant, thus increasing both the sludge available for biogas production and the amount of digestate as a raw material for fertilizer production. An efficient solids removal also decreases the load to the biological treatment stage, which reduces the energy required for aeration.

The SS removal by the primary filters can be increased by adding polymer to the wastewater prior to filtration. Lab scale tests of several commonly used polymers indicated that 75 % SS removal might be attainable at approximately 1-7 g of polymer per m3. Full scale tests suggested that an approximately 3 times higher concentration was required to reach 75 % SS removal in the plant. A rough cost-benefit analysis suggested that even with the best performing polymer, the polymer cost would exceed the expected monetary income from increased biogas production - or at best leave a very slim financial margin. Thus, given the substantial amount of polymer apparently required to obtain an operationally useful effect, further SS recovery over the filtering step by polymer addition is probably neither economically nor ecologically desirable.

- EBPR at SNJ, IVAR – improving the performance.

A prerequisite for controlled struvite precipitation at the SNJ plant is a well-functioning EBPR process, and optimization of this process is necessary for the goal of nutrient recovery to be viable. Due to the physical design of the bioreactor and settling tanks, establishing a robust and effective EBPR process has been a challenge since the commissioning of the biological treatment in 2018. While backflowing and short-circuiting in the bioreactor has been successfully improved, the 74 m long settling tanks are still an issue, and the long transport causes the biological sludge to become anaerobic and release phosphate before it is returned to the bioreactor. Rebuilding inlet arrangements and installation of baffles in the settling tanks has had a certain effect, but the phosphate release in the settling tanks is still too high to be able to achieve 75 % removal.

As part of the Wider Uptake scope, IVAR collaborates with the Norwegian University of Science and Technology (NTNU) on the challenges with EBPR. NTNU has built a model of the SNJ WWTP, which is being run under different conditions to identify measures with positive effects. Further optimization of the EBPR process awaits the results from the model experiments at NTNU

- Struvite production at SNJ, IVAR – P recovery as struvite

Several tests have been performed on controlled struvite precipitation at SNJ. Both lab and pilot scale tests (2021) have indicated that struvite precipitation within digested sludge could reach approx. 70 % ortho-P reduction by aeration alone. Aeration causes an elevation of the pH from 7,3 to approx..8 due to stripping of CO2, and P readily precipitates as struvite.

In 2022 a 16-liter Fluidized Bed Reactor (FBR) pilot was installed at SNJ to test the feasibility of struvite precipitation on thickening and dewatering reject streams. The idea is that a P-rich secondary sludge could be stimulated to release ortho-P by addition of VFA before dewatering, and the reject as a P-source. Controlled struvite harvesting would lessen the amount of ortho-P released in the digesters, reducing the risk of unwanted struvite precipitation in operational equipment. The secondary sludge reject (spiked with ortho-P to simulate 75 % P-removal conditions) and the ammonia-rich reject stream from digestate dewatering, was combined in the pilot reactor with a magnesium solution to form struvite crystals. NaOH was added to elevate the pH in the reactor. When Mg and NH4 to P-ratios were above 1, and pH above 8, P removal of 75% or more was easily obtained.

X-ray diffraction (XRD) analyses at the University of Stavanger have confirmed that the precipitate is mainly struvite. If 75 % P removal from the wastewater is obtained, 30 % of the total P load to the plant may be recovered as struvite while an additional 30-40 % of the P is recovered in the organic fertilizer.

Legislation and policy recommendations

It is mainly the EU's Sewage and Sludge Directive as well as the Fertilizer Product Regulations that has governed IVAR's work on sludge treatment. IVAR has focused on thermal drying /pelleting with completion at the fertilizer factory at SNJ. In parallel with this, IVAR has collaborated with other actors (formerly HØST et al.) to actively influence the authorities. The result of this is that we finally have a national regulatory framework adapted to IVAR's dried and pelleted fertilizer products (Minorga®). § 12a of the Norwegian legislation concerning organic fertilizers was added in 2018 to incorporate regulation of the Minorga® fertilizer

The upshot of this is that IVAR's fertilizer product is covered by special exemption provisions for wastewater-based sludge in the Fertilizer Product Regulations with, among other things, exemptions for demold requirements, and use. The challenges have been related to the content of zinc, which also includes exports. In addition, it must also be added that in agriculture there are divided opinions on the use of wastewater-based sludge.

Applied product

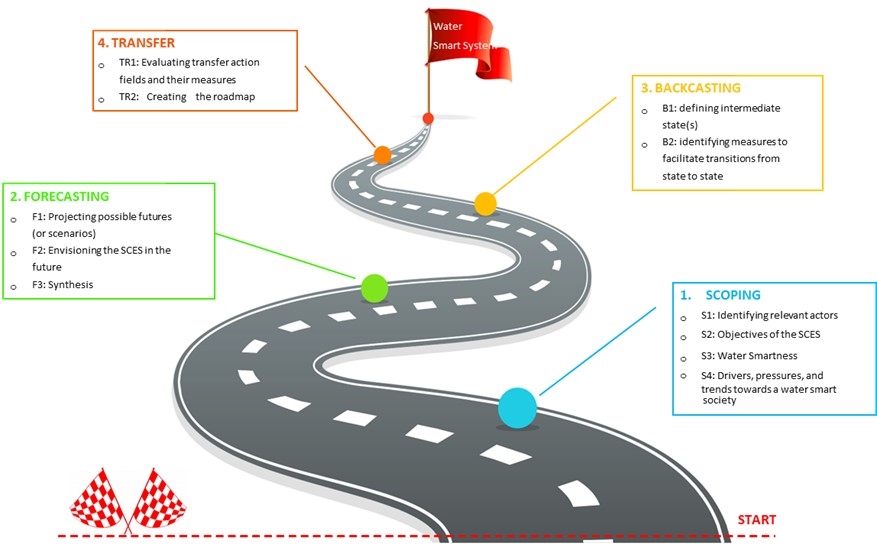

The WIDER UPTAKE roadmap guide

The WIDER UPTAKE roadmap guide, developed by the H2020 WIDER UPTAKE project, offers a comprehensive framework for imple…