Description

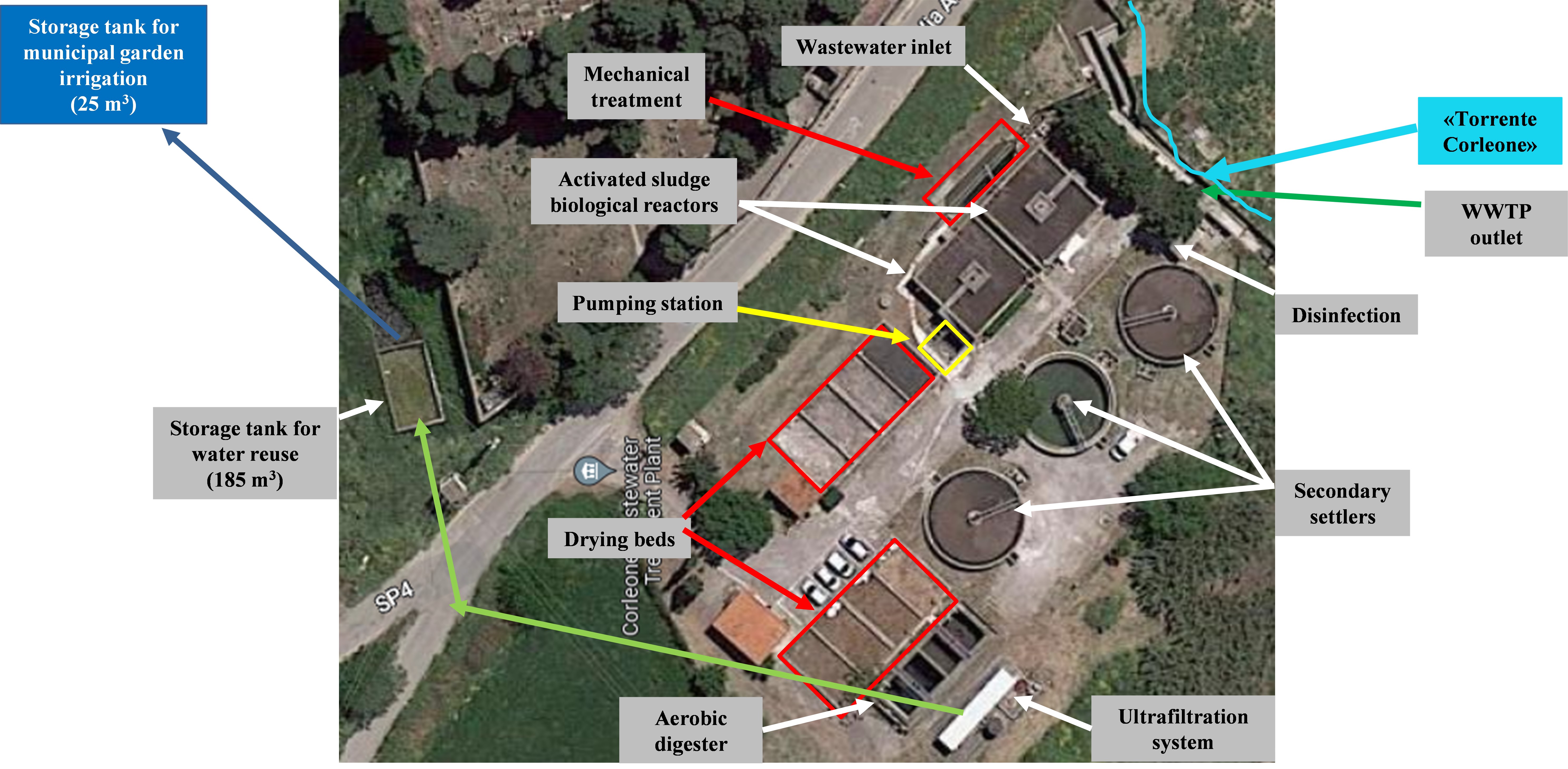

The Corleone case study consists of: i. wastewater treatment plant (WWTP); ii. ultrafiltration (UF) unit. The Corleone WWTP was designed for a daily flow rate of 3700 m3 day−1 corresponding to 12,000 inhabitant equivalents. The Corleone WWTP is a typical conventional activated sludge (CAS) process with a pretreatment stage (sieving and degritting) followed by two aerobic biological reactors with surface aeration and three final clarifiers. In detail, each aerobic reactor is characterized by a square shaped horizontal section with a length of 11 m and a water level of 3.2 m, corresponding to a net mixed liquor volume close to 390 m3. The WWTP has three identical final clarifiers, each characterized by a 12 m diameter and height of 1.75 m corresponding to a volume close to 200 m3. One of the three final settler is not in operation. After the final settling, there is a disinfection unit with sodium hypochlorite before the final effluent discharge, currently into a nearby river. The sludge line consists of two aerobic digesters, each with a volume close to 165 m3, and eight drying beds, with a horizontal surface equal to 40 m2.

WWTP has been recently subjected to: maintenance of pumps, replacing of aeration system (from superficial to pressure bubble), installation of flow rate measurement devices (influent and recirculation). Within Wider Uptake the pipeline was also installed for operating the water line as aerated activated sludge tank + anaerobic side-stream reactor (ASSR) to implement the oxic-settling-anaerobic (OSA) process in view of reducing sewage sludge production.

The WWTP also incorporates the UF unit for the final effluent filtration and a distribution network for water reuse (irrigation) in local agriculture and green urban areas (i.e., green gardens). The UF unit was designed for treating the maximum flow rate of 51 m3/h. The UF unit (Figure 2) is equipped of two sand filters, two membrane modules (each of 36 hollow fibers membranes made in PVDF), a clean in place reactor in which part of the filtrated water is collected and heated in view of performing every 14 days the membrane chemical cleaning by using 300mg/l Sodium Hypochlorite solution. The initial project considers two reservoirs for collecting water to be reused. However, before the starting of Wider Uptake project several issues related with the UF unit exist: i. the UF system was not in operation; ii. one of the two membrane modules was damaged; iii. the reservoirs and their connection with the UF unit were damaged.

Corleone case study is focused on water reuse, sewage sludge reduction, wastewater treatment plant optimization and reduction of GHG emissions. The main motivation moving the actions within Wider-Uptake project is the reduction operating costs and the resource (water) recovery.

Requirements and conditions

The reuse of treated wastewater represents a challenging issue in terms of regulatory; actually, the existing regulations do not facilitate the resource reuse process. One of the main constraints encountered was that AMAP spa was the operator only for the WWTP and not for the UF unit. Within Wider Uptake project an agreement between Corleone Municipality (owner of both WWTP and UF unit) and AMAP Spa was stipulated in view of assigning to AMAP the UF management. Furthermore, other technical constraints related with the UF unit were encountered: i. the UF system was not in operation; ii. one of the two membrane modules was damaged; iii. the reservoirs and their connection with the UF unit were damaged. Within the project the UF unit was started with only one membrane module (treating 30 m3/h of water), a tank for collecting water to be reused was individuated. Treated water will be transported to nearby farmers by trucks.

Applied product

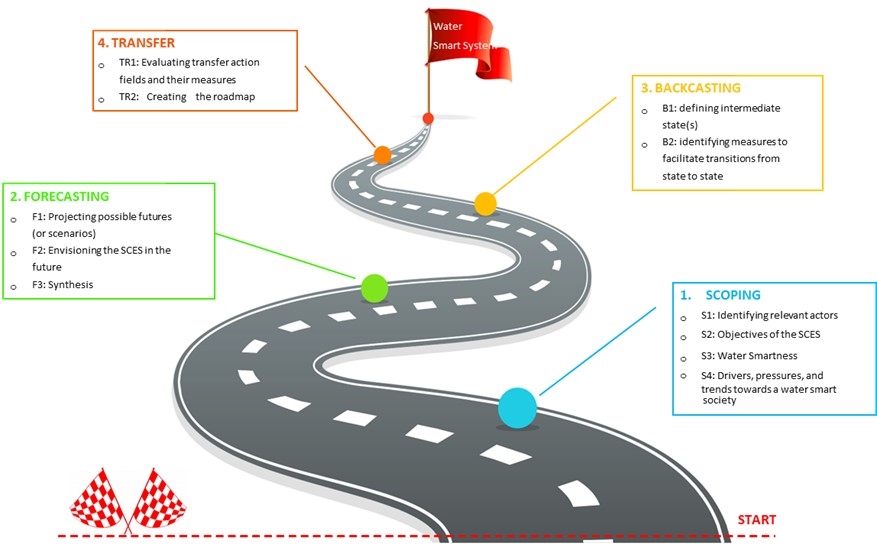

The WIDER UPTAKE roadmap guide

The WIDER UPTAKE roadmap guide, developed by the H2020 WIDER UPTAKE project, offers a comprehensive framework for imple…