Description

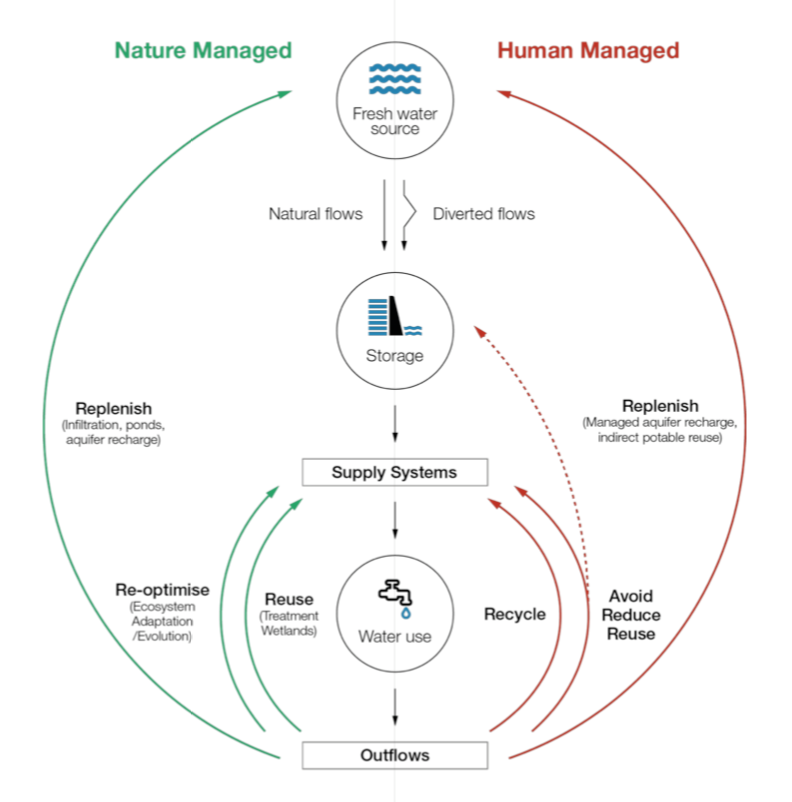

The BASF Antwerp case study focuses on optimizing water use, reuse, and alternative water sources to address increasing salinization of port water and declining freshwater availability. BASF Antwerp, the largest water consumer in the port, primarily uses water for cooling / heat transfer. The project aims to reduce water intake from the port and increase internal water reuse through three main strategies: enhanced cooling water recirculation, treatment of reverse osmosis (RO) concentrate for potential reuse, and utilizing condensates as spraying water for air-cooled chillers. To achieve these goals, pilot studies using the MERADES and IMPROVED units were conducted to simulate cooling circuits and test various water treatment technologies. The results demonstrated potential reductions in water withdrawal and improvements in water quality, supporting the transition toward more sustainable and circular water management.

Applied technologies

Best practices

-

Modular System Architecture:

Technologies should be deployed using a modular design to facilitate scalability, maintainability, and adaptation to variable wastewater compositions. -

Comprehensive Pretreatment Strategy:

Pretreatment steps such as filtration and pH adjustment are essential to prevent membrane fouling and ensure stable operation of downstream units. -

Automation and Monitoring Integration:

The use of automated control systems and real-time monitoring tools is critical for optimizing operational parameters, responding to fluctuations in influent quality, and minimizing energy and chemical consumption. -

Pilot Testing Under Real Conditions:

Pilot-scale validation under site-specific conditions is recommended prior to full-scale implementation to assess performance, integration feasibility, and compliance with regulatory requirements. -

Energy Optimization Measures:

Thermal processes should be designed with energy efficiency in mind, incorporating heat recovery and system integration where feasible to reduce operational costs. -

Cross-Functional Coordination:

Effective coordination between engineering, operations, and environmental compliance teams throughout design and operation phases enhances system reliability and ensures alignment with site objectives. -

Maintenance and Cleaning Protocols:

Site-specific clean-in-place (CIP) procedures should be established and routinely executed to manage fouling and maintain treatment efficiency. -

Management of Concentrated Residual Streams:

Concentrated waste outputs must be monitored and managed according to site capabilities and environmental regulations to avoid downstream impacts or bottlenecks.

Technology performance and best practices

The most effective configuration was found to be a hybrid system combining RO (primary treatment), MD (secondary polishing), and EC (final concentrate handling). The numerical metrics are:

-

Reverse Osmosis (RO)

-

Permeate Recovery Rate: ~70–80%

-

Conductivity of Permeate: Below 20 µS/cm

-

Organic Matter Removal: Over 95% (indicated by TOC and COD reduction)

-

Operational Pressure: ~12–15 bar

-

-

Membrane Distillation (MD)

-

Recovery Rate: >80%

-

TOC Removal Efficiency: >98%

-

Temperature Used: ~60–80°C

-

Condensate Conductivity: <10 µS/cm

-

Concentration Factor: Up to 10×

-

-

Evaporation and Crystallization (EC)

-

Water Recovery: Up to 90–95%

-

Dry Residue Recovery: Crystallized salts recovered from brine

-

Energy Consumption: Significantly higher compared to RO and MD

-

-

Overall System Integration

-

Combined Recovery: >95% of water reclaimed from challenging streams

-

Final Effluent Quality: Suitable for internal reuse or discharge according to regulations

-

Synergistic benefits

- Enhanced Water Reuse Efficiency:

By integrating RO, CCRO, and EDI, BASF improved water recovery rates while maintaining high-quality standards. The combination of these technologies allowed for the reuse of process condensate and boiler blowdown, significantly reducing freshwater intake and minimizing wastewater discharge. - Optimized Cooling System Performance:

The use of the MERADES pilot and digital modeling enabled better control over cooling water cycles. By simulating different scenarios, BASF identified safe operational limits for increased recirculation, reducing overall water withdrawal while mitigating risks like scaling and corrosion. - Energy Savings & Process Optimization:

The integration of digital twins with cooling tower models allowed for dynamic energy efficiency calculations. By optimizing fan operation in forced draft cooling towers, BASF reduced energy consumption, leading to cost savings and lower environmental impact. - Improved Chemical Management:

The combined use of anti-scaling treatments, pH control, and advanced membrane processes reduced the need for excessive chemical dosing. This not only enhanced process stability but also minimized chemical waste and potential environmental contamination.

Requirements and conditions

- Technical Requirements & Constraints:

BASF had to evaluate risks like scaling, fouling, and corrosion in cooling water recirculation. Advanced water treatment methods, such as RO, CCRO, and EDI, were tested for efficiency. Ensuring membrane protection, optimizing chemical dosing, and adapting infrastructure were critical for successful implementation. - Operational & Logistical Constraints:

Pilot testing was conducted at Laborelec instead of BASF due to site-specific challenges. Transporting water for offsite testing, setting up sensors, and ensuring stable power supply posed logistical issues. Full-scale implementation required significant financial investment, influencing prioritization of certain solutions. - Environmental & Regulatory Considerations:

Climate change increased port water salinity, affecting sourcing strategies. Strict quality requirements had to be met for boiler feed water reuse. Compliance with industrial safety and environmental regulations was essential, aligning with BASF’s sustainability goals of reducing water withdrawal and optimizing resource usage. - Digital & Modeling Constraints:

Developing a digital twin for cooling optimization required additional sensors and real-time data collection. Hybrid models were built to predict corrosion rates and optimize cooling tower operations. Continuous validation of these models ensured they remained aligned with site-specific conditions and industrial process requirements.

Key lessons

- Water Quality Variability Requires Adaptive Solutions:

Fluctuations in feedwater quality, such as varying salinity levels and organic content, affected process performance. The need for flexible treatment configurations, including pre-treatment adjustments and alternative regeneration methods, was crucial for stable and reliable operation. - Synergistic Use of Technologies Enhances Sustainability:

The integration of multiple technologies, including RO, CCRO, EDI, and digital modeling, demonstrated that no single solution could address all challenges. A combined approach allowed for higher water recovery, lower chemical consumption, and optimized energy efficiency. - Digital Modeling and Data Analysis Improve Decision-Making:

The development of thermal and corrosion models, as well as digital twins for cooling towers, provided valuable insights into process optimization. Real-time data analysis helped in proactive maintenance, reducing scaling and corrosion risks while improving operational stability. - Economic and Technical Feasibility Must Be Balanced:

While significant water savings were technically achievable, economic constraints played a key role in decision-making. The high costs of infrastructure modifications required for large-scale implementation emphasized the need for cost-benefit analysis before adopting new water reuse strategies. - Collaboration and Stakeholder Engagement Drive Success:

Close cooperation between industry partners, technology providers, and academic institutions was critical for developing effective solutions. Regular technical meetings, onsite visits, and communication with local stakeholders ensured alignment with operational needs and regulatory requirements. - Process-Specific Challenges Require Tailored Approaches:

Different industrial water streams (cooling water, process condensate, boiler blowdown) required customized treatment solutions. The inability of RO and IEX to remove small organic molecules like ethanol and methanol emphasized the need for targeted biological treatment where necessary. - Continuous Monitoring and Adaptation Are Key:

Unexpected issues, such as silica deposition on CCRO membranes and iron/zinc fouling in NTBA water treatment, demonstrated the importance of ongoing monitoring. Adaptive measures, including cleaning protocols and process modifications, were necessary to maintain performance over time.

Lessons learned from technology operation

1. Required Technical Expertise for Operation and Maintenance

Operating advanced water treatment technologies like CCRO, EDI, and NTBA required specialized knowledge in membrane performance, ion exchange chemistry, and system diagnostics. Proper training of personnel was crucial to ensure efficient operation and timely troubleshooting.

2. Importance of Regular Maintenance and Cleaning Protocols

Scaling, biofouling, and particulate deposition impacted membrane performance and system efficiency. Scheduled cleaning procedures, including optimized CIP (clean-in-place) cycles, were essential for maintaining long-term reliability and reducing downtime.

3. Monitoring and Control Systems Reduce Technological Risk

Real-time data analysis and digital modeling significantly minimized the risk of process failure. By continuously tracking key performance indicators (KPIs) such as conductivity, silica levels, and corrosion rates, operators could implement corrective actions before major issues arose.

4. Process Downtime Can Be Minimized with Redundancy Strategies

Unplanned downtimes due to membrane clogging or system malfunctions emphasized the need for redundancy in critical process units. Parallel treatment lines, backup filtration systems, and rapid-response maintenance teams helped mitigate disruptions and maintain continuous water supply.

5. Customization of Treatment Processes Based on Feedwater Composition

Variability in feedwater quality affected system performance, requiring adjustments to operational settings. Process-specific optimizations, such as adjusting anti-scalant dosing in RO systems or modifying ion exchange regeneration cycles, were necessary for consistent efficiency.

6. Energy Efficiency Must Be Considered in Process Design

While advanced treatment technologies improved water recovery, energy consumption remained a key concern. Implementing energy-saving measures, such as pressure recovery in RO systems and optimized recirculation rates, helped reduce operational costs and environmental impact.

7. Long-Term Performance Depends on Material Compatibility

Corrosion and fouling issues in cooling water circuits demonstrated the importance of selecting suitable materials for pipes, membranes, and exchangers. The use of corrosion-resistant alloys and proper chemical dosing strategies extended equipment lifespan and reduced maintenance costs.

8. Adaptability to Changing Regulatory and Operational Conditions

Stringent discharge regulations and evolving industrial needs required a flexible approach to process control. The ability to modify treatment strategies based on regulatory updates or production changes ensured long-term compliance and operational sustainability.

Publications and references

- Development of a hybrid model for reliably predicting the thermal performance of direct contact countercurrent cooling towers

Chamanthi Jayaweera a, b, c, ∗, Niels Groot d, Steven Meul e, Arne Verliefde a, c, Ingmar Nopens a, b, Ivaylo Hitsov a, b, c

a Centre for Advanced Process Technology for Urban REsource recovery, Frieda Saeysstraat 1, 9052, Gent, Belgium

b BIOMATH - Model-based analysis and optimisation of bioprocesses, Department of data analysis and mathematical modeling, Faculty of Bioscience Engineering, Ghent University, Coupure Links 653, 90 0 0, Gent, Belgium

c PAINT – Particle and interfacial technology, Department of green chemistry and technology, Faculty of Bioscience Engineering, Ghent University, Coupure Links 653, 90 0 0, Gent, Belgium

d Dow Terneuzen, Netherlands

e BASF, Antwerp, Belgium

https://doi.org/10.1016/j.ijheatmasstransfer.2022.123336