Description

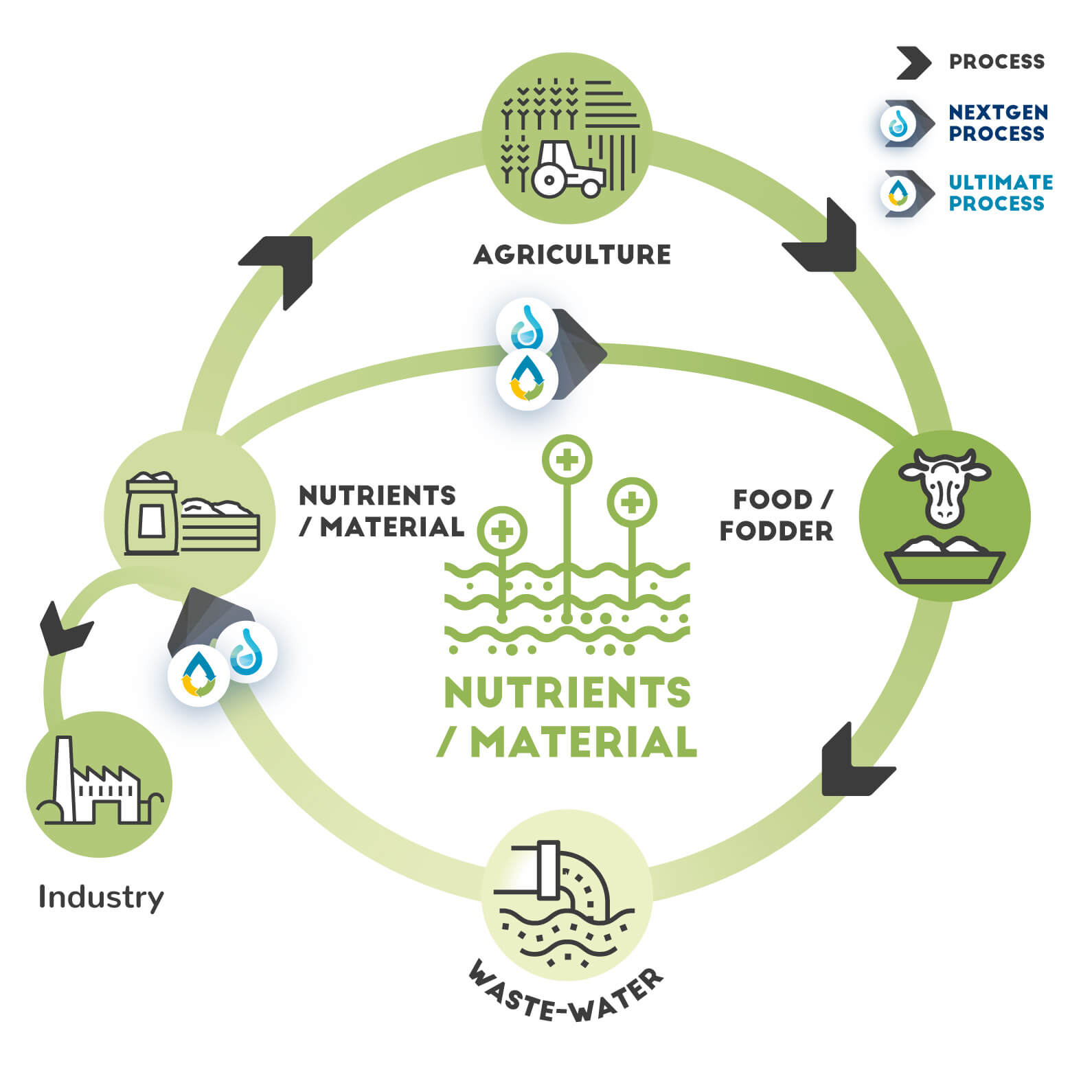

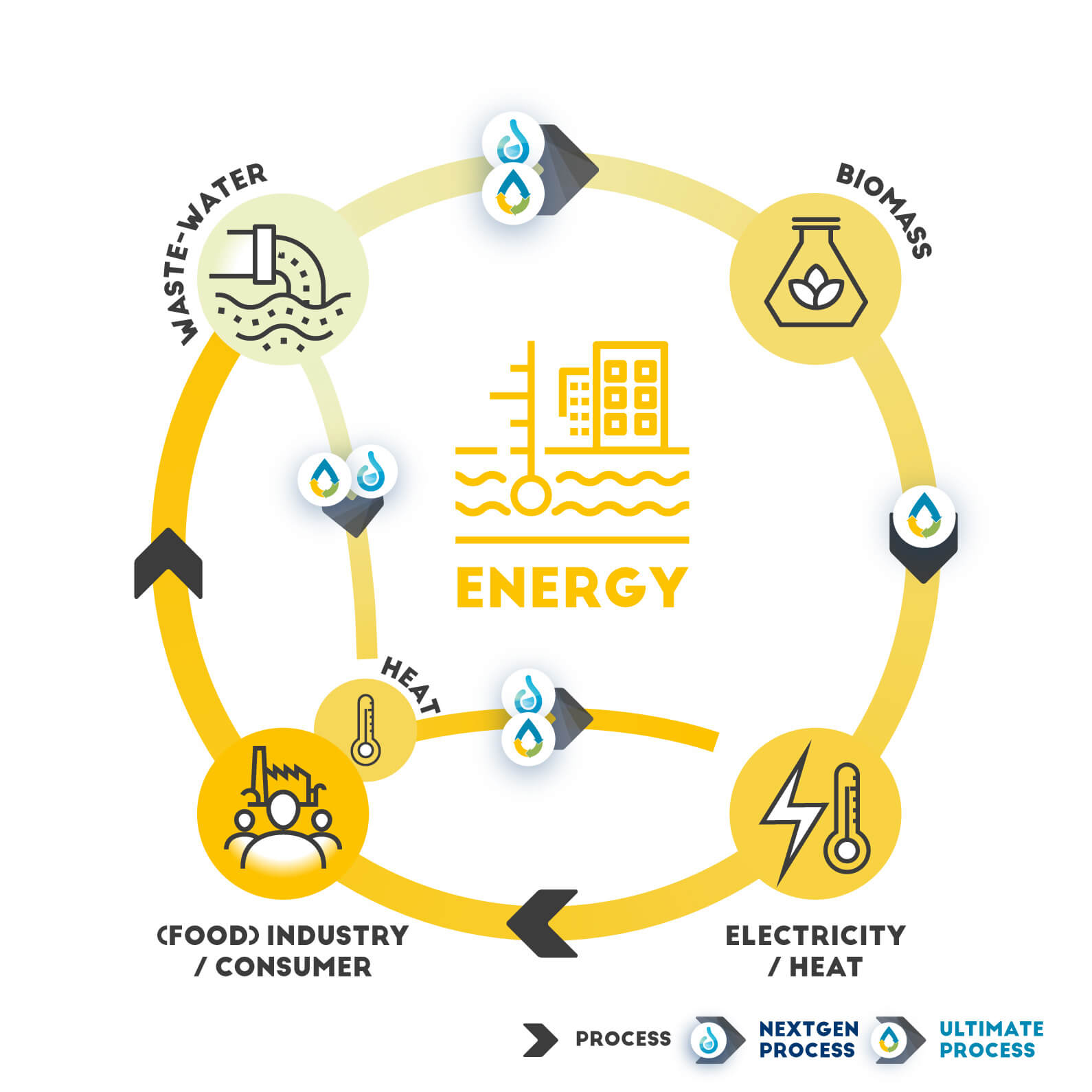

The Alicante Living Lab aims to exploit 100% of the reuse potential in the region and to promote circular economy strategies both at the Rincón de León WWTP and in the region. In the water-energy vector, solutions for the co-digestion of oils and greases or the installation of microturbines for energy recovery from wastewater treatment plant effluents are evaluated. In the water-resources vector, ion exchange membrane technologies are evaluated to maximise the recovery of reclaimed water, as well as the recovery of raw materials from current reverse osmosis rejects. On the other hand, evaporation and crystallisation solutions are evaluated for the recovery and valorisation of nutrients in the sewage sludge line.

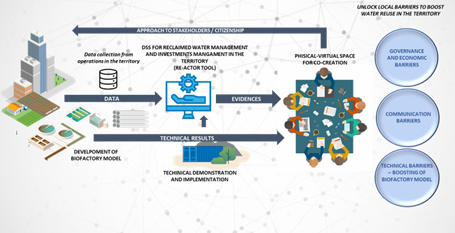

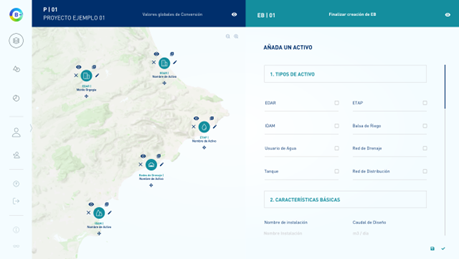

Within the framework of the Living Lab on reuse, a digital decision-making support tool has been developed for the evaluation of new investments and actions related to water reuse and circular economy solutions within the urban water cycle. The scope of application is at regional level.

Applied technologies

Facts of the applied technologies

Anaerobic co-digestion:

- Digester capacity 1 m3

- Two co-substrates tested from different industries: cream waste and fruits and vegetables

- Hydraulic retention time was 25 days

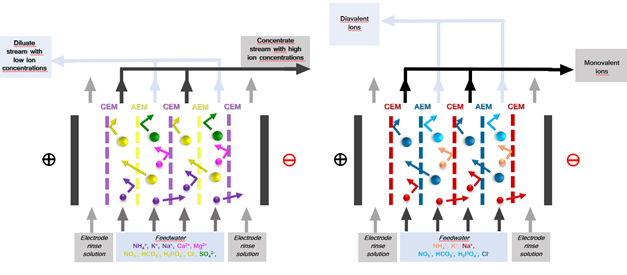

Brine valorization train (Selective electrodialysis + Electrochlorination):

- NaClO production capacity (by electrochlorination): 140 L/h

- FAC concentration of product: 4,500 ppm FAC

CEVAP for ammonia recovery

- Treatment capacity of pilot 100 L/h

- Heat input temperature up to 90ºC

- 4 effects (cartridges)

Microturbine:

- Installed capacity of picoturbine 2kW

- Nominal flow of turbine 0.3 m3/s

- Head of turbine 0.8 m.

RE-ACTOR tool:

- Includes several indicators for assessing plant upgrades and support decision-making towards including CE technologies: Eutrophication, Carbon footprint, CAPEX, OPEX.

Key performance indicators

- Increase biogas production compared to anaerobic mono-digestion

- Recover energy from the vortex movement in WWTP’s effluent prior to discharge

- Separate divalent ions in brines in a stream aimed at reclaimed water

- Concentrate monovalent ions in brines for producing hypochlorite sodium

Best practices

Best practices for constructing and operating the applied technologies in Alicante LL include thorough assessment and meticulous planning of resources when recycling pilot plants from previous projects to prevent disruptions. A well-conceived mitigation plan is essential for expedited decision-making during deviations. Careful planning is required for commissioning pilot plants, considering health and safety factors. Addressing global shortages of electronic components is crucial to avoid construction delays. In-person training and contingency planning, as demonstrated in the CEVAP and Brine Valorization projects, facilitate smooth operations and integration. For microturbines, a detailed preliminary design considering site-specific conditions and seasonal variations is vital. Effective co-digestion practices involve collaboration with waste producers, evaluating the business model, and managing seasonal variations in waste production to ensure a consistent supply of co-substrates.

Requirements and conditions

Anaerobic co-digestion:

- Crushing pre-treatment necessary for some waste type (fruits and vegetables)

- Temperature in sewage+waste mix needs to be maintained low (4ºC) to prevent degradatio

Brine valorization train (Selective electrodialysis SED + Electrochlorination):

- Concentration of NaCl in the stream produced by SED needs to be above 10 g/L.

- Water hardness needs to be below 17 mg/L prior to EC.

CEVAP for ammonia recovery

- Ammonia-rich vapours were produced so Health & Safety requirements apply.

Outcome of assessments

Anaerobic co-digestion with organic waste from local industries has been validated to be a suitable technology to increase biogas production at a pilot scale. The challenge of this technology is to find enough waste volume on an annual basis, and guarantee a continuous substrate provision to the digesters.

Key lessons

With regard to the RE-ACTOR tool, the methodology followed to carry out the categorization and parameterization of the technologies to be integrated in the backend is user-friendly, easily updatable and upgradable, which enables quick addition of new technologies and parameters. In general terms, the RE-ACTOR tool can be easily updated to a highly ambitious tool that provides valuable support in the preliminary stages of design and assessment of technologies tested in the Alicante LL and other water treatment technologies. The simultaneous development of formulas and algorithms alongside the front-end interface platform hindered smooth progress in the overall tool development due to suboptimal synchronization between teams. This supposed deviations in terms of development costs.

In this sense, the overall planning of the tool development task should have been extended, especially at the beginning stages to have more time allocated to improve the back-end, and therefore enable a smoother interface design and programming.

Lessons learned from technology operation

General:

- Including pilot plants recycled from previous or concurrent projects makes it really important to thoroughly assess existing systems and meticulously plan the resources needed for equipment updates and repairs to prevent disruptions and deviations.

- Setting a well-conceived mitigation plan is crucial for expediting decision-making and subsequent actions in case of deviations led by pilot plants.

- The commissioning of pilot plants at the facility requires careful planning, including thorough consideration of health and safety factors. These factors may include heat during the summer months and the potential presence of mosquitoes.

- Global electronic component shortage occurred in 2022-2023, which delayed the construction of pilot units.

CEVAP:

- As part of the contingency plan set for this technology, an in-person training at the facilities where it was installed previous to Alicante to the AMAEM staff in charge of its operations was highly useful.

- Relying on recycling the pilot unit from another ongoing project has led to delays in installing the pilot at Alicante LL.

- The CEVAP can concentrate ammonia to a certain level, but far from a commercial ammonia reagent.

- Being an evaporative technology, increasing the temperature (i.e. OPEX) is a requirement although temperatures necessary are much lower than in conventional evaporators. This could be achieved with waste heat generated in the cement industry that currently carries out a thermal drying of the sewage sludges of Alicante WWTP.

Brine Valorization:

- A training was carried out at the subcontracted engineering firm that constructed the pilot plant before its transport and installation at the WWTP. This action helped the operators to gain knowledge and time before its commissioning.

- The brine treatment train consisted of technologies from different technology providers and its integration. Preliminary tests of the integration of pilot units is a complex task and needs sufficient time allocation to guarantee a successful integration.

Microturbines:

- Carrying out a preliminary design with dimensions and site specifications and requirements is fundamental for a smooth task progress and turbine construction.

- In WWTP it is really important to have previously identified and in mind the seasonal and daily variations of water flow for an optimal design.

- Energy production through microturbines with water effluents in WWTP would make more sense in much bigger installations than Rincón de León WWTP that treat higher water flows.

Co-digestion:

- A good relationship was established with two local companies from the beginning of the project and were willing to collaborate providing waste.

- The co-substrates assessed in the project are suitable for co-digestion but their current production (Tn/year) are not enough for full scale implementation

- The business model of waste management and co-digestion needs to be carefully evaluated together with the waste producers.

- A waste manager as mediator can offer the service of managing waste from industries and provide it for co-digestion.

- Seasonal variations of waste production from the companies is also a key point to take into account for co-digestion studies.

Legislation and policy recommendations

- European regulation on minimum requirements for water reuse (EU 2020/741)

- Spanish Royal Decree 1620/2007 for water reuse.

Applied product

RE-ACTOR

DSS for the evaluation of new investments and actions related to water reuse and circular economy solutions within the …