Description

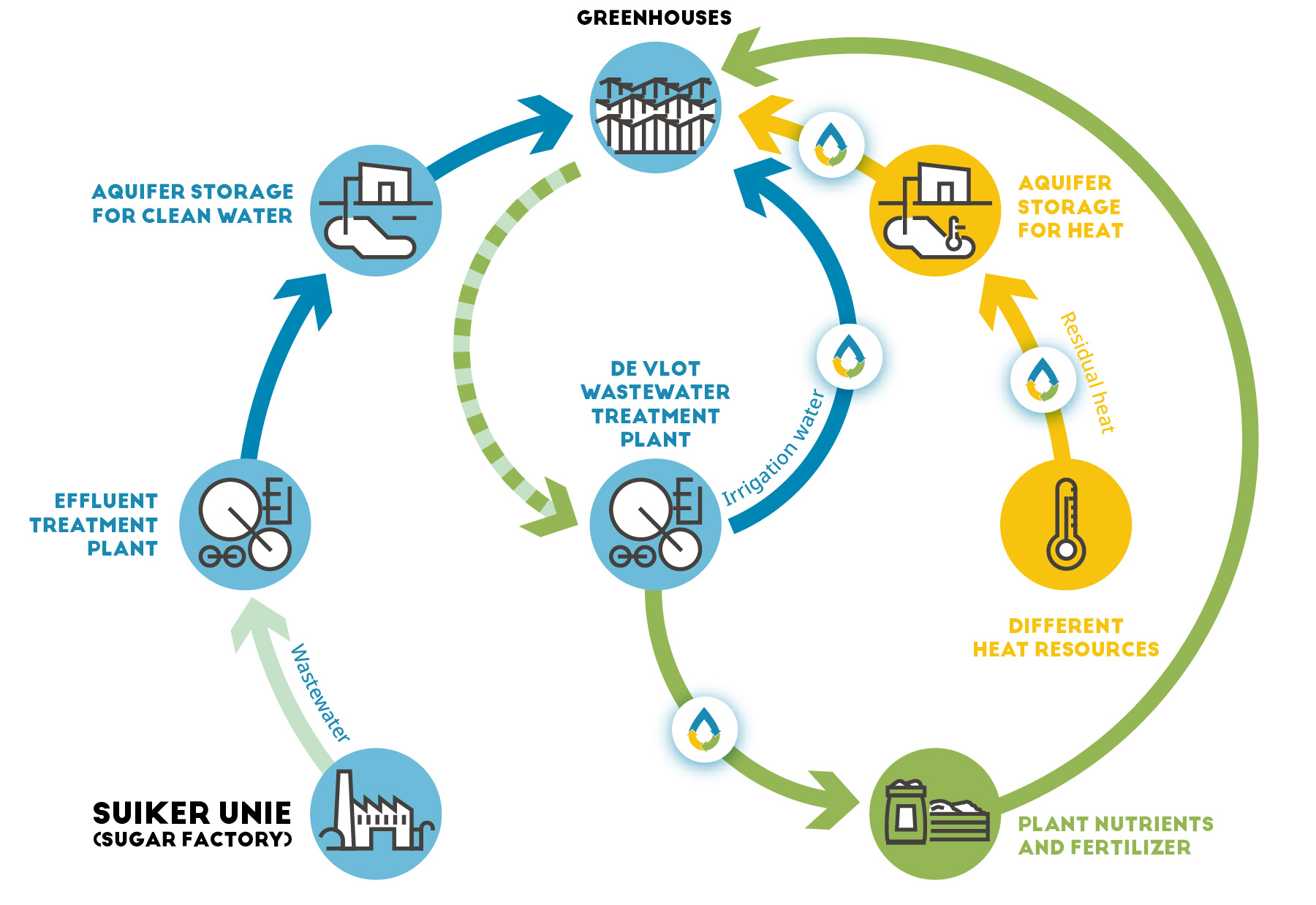

Coöperatieve Tuinbouw Water Zuivering de Vlot is a wastewater treatment facility located at ‘s- Gravenzande treating 160 hectares (60 companies) of wastewater from greenhouses mainly growing ornamental crops. Exploring water and nutrient reuse oppurtunities for their facility, they are optimizing their system for internal symbiosis within their own facility and external symbiosis with neighbouring greenhouses and industries. De Vlot has ambitions to reach zero liquid discharge and provide symbiotic internal and potentially external reuse of water and nutrients from greenhouse wastewater (approx. 10% of the total water input). The system to treat and reuse drainwater from 60 greenhouses (160 ha) is laid out maximum capacity of 60 m³/h but the expectation is that the majority of the time, 40 m³/h is sufficient (for one out out 3 treatment streets to be in maintenance if required). In this setup, recycling would be provided internally for the greenhouses in the summer and in the winter months the excess recovered water and nutrients can be reuse in nearby industries or a central water bank.

In the case study the following technologies are investigated:

1) use of electrodialysis for treatment of greenhouse wastewater - specifically selective sodium removal - to produce a water quality fit for irrigation purposes

2) feasibility of high-temperature aquifer thermal energy storage (HT-ATES) to balance heat supply and demand across the year.

Applied technologies

Technology performance and best practices

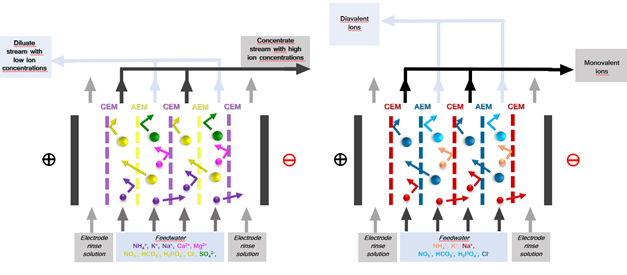

Water reclamation from greenhouse wastewater

In the Dutch case study, greenhouse wastewater was treated by electrodialysis (ED) and capacitive electrodialysis (CED) to reduce salinity and produce irrigation water with low conductivity (<0.2-1 mS/cm) and low sodium and chloride content (<0.1 mmol/L). ED effectively removed monovalent ions such as chloride and nitrate, achieving approximately 90% reduction in electrical conductivity, although divalent and trivalent ions (e.g. sulphate, calcium, magnesium, phosphate) were removed more slowly. The system showed strong performance for the removal of monovalent ions, with specific energy consumption (SEC) of 0.12-0.14 kWh/m³. (C)ED demonstrated high quality irrigation water over different feed types with variable ion removal efficiencies. Sodium removal was lower than calcium and magnesium removal (86%, 97% and 98% respectively for target conductivity <0.2 mS/cm), influenced by voltage and water recovery. The energy efficiency and adjustable ion removal of (C)ED make it a promising sustainable alternative to conventional desalination, especially for irrigation water and nutrient recovery in greenhouse horticulture. Overall, (C)ED showed potential as a sustainable solution for water recovery from greenhouse wastewater, achieving 60-90% water recovery and providing recycled water equivalent to 16% of the consortium's total freshwater consumption.

Nutrient recovery from greenhouse wastewater

The Dutch case study also analysed the feasibility of using the electrodialysis (ED) technologies to recover nutrients from the greenhouse effluents. To this end, monovalent selective membranes were modified and tested to reduce the concentration of harmful ions (Na+ and Cl-) and improve the potential for nutrient reuse in greenhouse cultivation. It was estimated that the ULTIMATE solution can achieve up to NO3- (30%), K+ (33%), Ca2+ (70%), Mg2+ (76%), SO42- (84%), PO43- (93%) nutrient recovery by treating greenhouse effluent. However, improvements are still needed in the development of highly selective monovalent membranes to improve the treatment process. In order to scale up and replicate this material recovery technology on a large scale, it should be considered that a high concentration of nutrients in the feed water is beneficial to improve the recovery rate of the ED technology. On the other hand, tests are needed to evaluate the uptake of recovered nutrients by plants. In addition, new regulatory requirements for the management of this type of wastewater may provide input for the further development of this technology.

Outcome of assessments

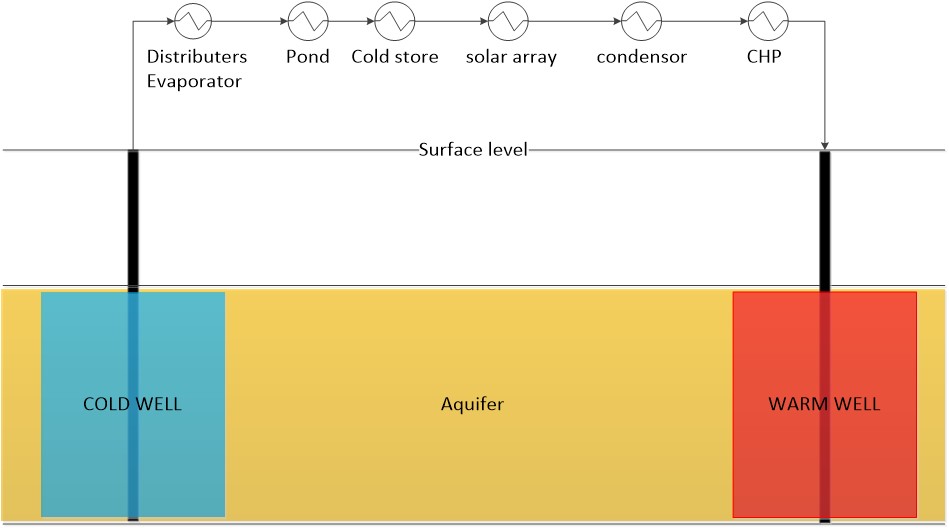

Feasibility of using a high temperature Aquifer Thermal Energy Storage (HT-ATES)

As part of the Case Study, the feasibility of using high temperature Aquifer Thermal Energy Storage (HT-ATES) system to balance the seasonal imbalance between heat supply and demand in the greenhouses was assessed. The potential to use HT-ATES to store excess heat from a geothermal plant during the summer and recover it to supplement the heat supply from this source during the winter was characterised by analysing the actual supply and demand, studying the geohydrology at the site to determine the suitability of the subsurface for HT-ATES and predict the performance, assess the financial feasibility and map the local governance situation with regards to permits. This assessment concluded that the aquifer present is very suitable for installation of HT-ATES wells and that there is potential to increase the efficiency of sustainable heat delivery from the geothermal wells to the greenhouses in a cost efficient manner. The full report can be accessed here.

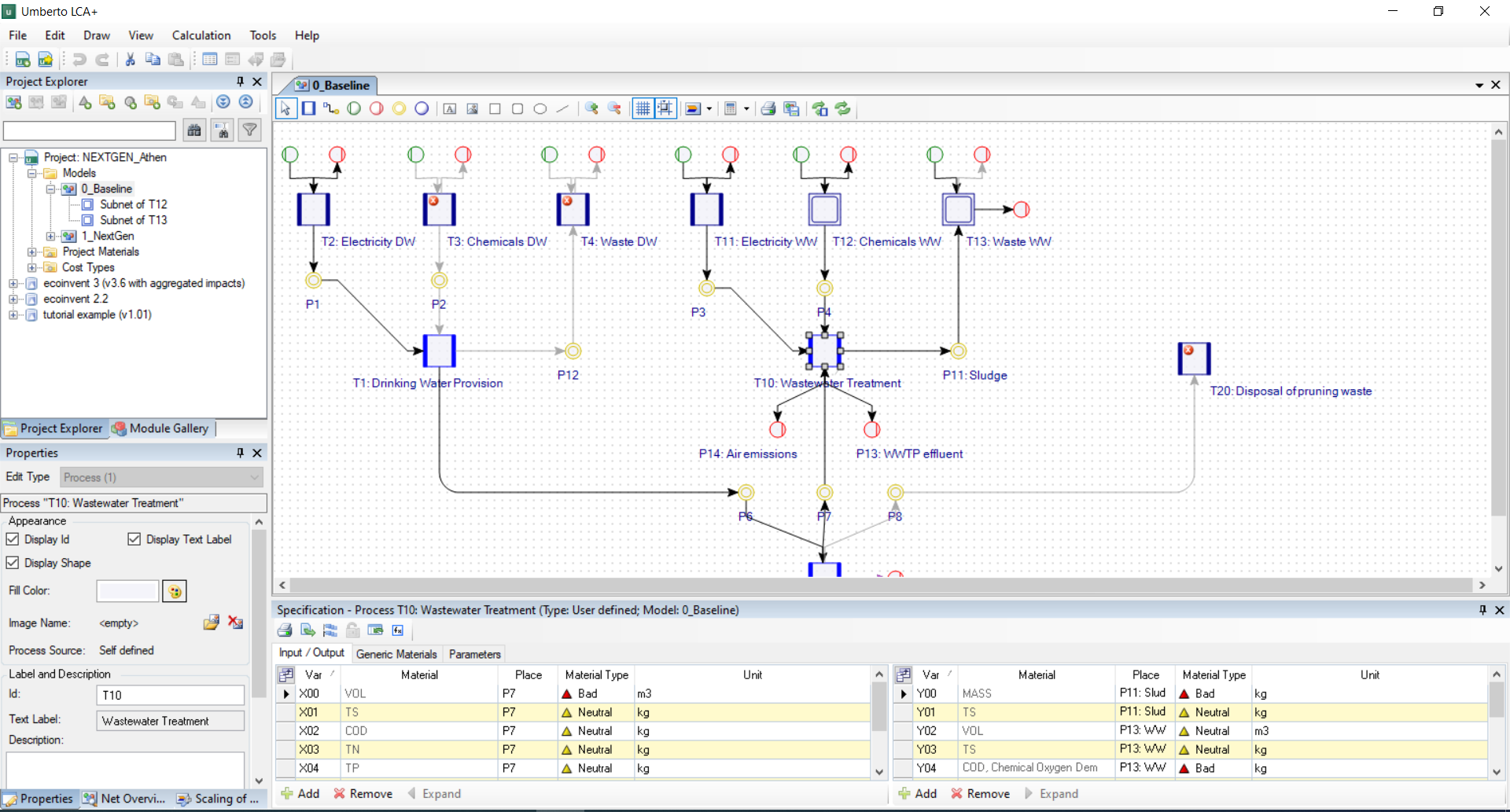

Life cycle assessment

Water reuse with ED: Compared to reverse osmosis, electrodialysis is a low-energy process capable to produce high-quality irrigation water from pre-treated greenhouse wastewater. Thus, ED can save on energy demand (-60%) and related greenhouse gas emissions (-65%) for water reuse, and also has lower impacts than local drinking water production. Brine disposal is still a challenge also for ED, and is not included in this assessment so far.

HT-ATES: Seasonal storage of renewable heat in a high-temperature ATES system has a lower greenhouse gas (GHG) footprint than fossil heat, even if the renewable heat source (here: geothermal well) is included in the total balance. Compared to heat from natural gas, HT-ATES saves 78% in GHG emissions, while still saving 55% in GHG in relation to co-generated district heat. With an increasing share of renewables in the grid electricity mix, the GHG benefits of HT-ATES will further increase in the future, as electricity is the main driver of its GHG profile.

Total cost of ownership (TCO)

The TCO assessment evaluates the financial viability over a 30-year period of using an electrodialysis (ED) system at a wastewater treatment plant for treating greenhouse wastewater with a capacity of 40 m3/h. The assessment suggests that implementing and operating the ED system requires an annual investment of about 114,000 EUR, with potential annual savings of 144,000 EUR from nutrient reuse. Over 30 years, this could result in a net profit of 17,000 EUR if nutrients are reused; otherwise, it could lead to a loss of 310,000 EUR. The main cost drivers are energy consumption and electricity prices, with operational costs largely influenced by the system’s energy requirements. A sensitivity analysis shows that both lower energy consumption and electricity prices are crucial for positive returns, highlighting the importance of optimising these factors for economic feasibility.

Legislation and policy recommendations

To investigate the potential of the implementation of an HT-ATES, test drillings to characterise the subsurface are expensive and time consuming. They are considered as a barrier for an easy market uptake of this technology. Hence, more research and demonstration projects are recommended to establish inexpensive, reliable and innovative technologies and their combinations in order to avoid uncertainties during planning of an HT-ATES and to accelerate the planning process. The highest risks are considered to be uncertain permit procedures and public perception. Furthermore, the permit procedure for a HT-ATES requires usually several years. We strongly suggest accelerating this procedure and to promote the demonstration of full-scale pilot systems in order to develop suitable policies and to show in practice that HT-ATES is a renewable, clean and safe technique. (see also D1.10)

Applied product

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…