Description

Steinhof, near Braunschweig, has a long tradition of water and nutrient reuse. Already at the end of the 19th century, fields were irrigated with sewage. From 1954 on, the wastewater was mechanically clarified and reused for irrigation. Finally, in 1979, the wastewater treatment plant (WWTP) was built and comprised a conventional activated sludge treatment system and a digestion stage. Until 2016, in summer, the digestate was directly reused in agriculture, while in winter, the digestate was dewatered and stored until the summer season. However, due to the new legislation in Germany, since 2017 only 60% of the digestate can be applied on the fields. The reasons are restricted periods for fertilizing with digested sewage sludge and the limitation of the nitrogen load to the agricultrual fields. Thus, the other 40% of the digestate were dewatered and incinerated.

In 2019, a new circular economy concept was implemented. Here, energy recovery technologies are combined with nutrient recovery technologies. Therefore, sludge managemet concept was adapted to increase the nutrient recovery rate and simultanously, as a synergetic effect, the biogas recovery rate increased. Hence, circular economy solution comprises a thermal hydrolysis process between two digestion stages and a full-scale nutrient recovery plant consisting of a struvite production unit to recover phosphorus and an ammonium sulphate solution production unit to recover nitrogen.

The secondary fertilizers are will be reused by the local farmers and the produced energy in the form of biogas and heat is reused by the plant itself.

Applied technologies

Technology performance and best practices

Enhancing biogas formation via thermal pressure hydrolysis

The goal of the Braunschweig (DE) case was to enhance biogas production via thermal pressure hydrolysis at the municipal WWTP. Thermal pressure hydrolysis (TRL 9) was performed as a pre-treatment of digestion, resulting in higher biodegradation during digestion. The results showed that the biogas production increased by 20% and the dewatering efficiency of the digestate increased by 10% due to the higher biodegradation of the thermally hydrolysed sludge. Although high attention to operating and maintenance of the system is mandatory, the technical feasibility of the thermal pressure hydrolysis has been successfully demonstrated. The better biodegradation contributed also to an increase in phosphate and ammonium concentrations in the liquor, which are crucial for the subsequent nutrient recovery. Detailed results can be found in D1.4.

Nutrient recovery (struvite, ammonium sulphate)

Nutrient recovery at TRL 9 was successfully demonstrated. To remove and recovery phosphorus, the struvite production unit used the liquor of dewatered digestate in a side stream and reached recovery rates between 80%-97%. The recovery rate depended highly on the chemical composition of the liquor, the mixing conditions in the precipitation reactor and the dosing rates of MgCl2. The potential for struvite production is 300 t struvite/a. This corresponds to 16% of the phosphorus influent load and to 1% of the nitrogen influent load to the WWTP. Detailed results can be found in D1.5.

For nitrogen removal and recovery, an air stripping and scrubbing unit was implemented to produce ammonium sulphate solution. The recovery rates were easy to control and could be operated between 80% and 97% as required. The potential for the production of (NH4)2SO4 solution is 2000 t/a corresponding to 175 t N/a, which is 12% of the inflow nitrogen load to the WWTP. Detailed results can be found in D1.5.

Outcome of assessments

Life Cycle Assessment

The combined sludge and sludge water treatment scheme with thermal pressure hydrolysis, struvite recovery and ammonium sulphate solution recovery is able to recover nutrients with a net-zero CO2 footprint. Direct N2O emissions and emissions of reactive nitrogen species are reduced. A further reduction of the CO2 footprint could be achieved by utilisation of excess heat in summer for the stripper to reduce caustic soda consumption. Further LCA results can be found in D2.1.

Life cycle costing & cost effectiveness analysis

The implementation of a combined sludge and sludge water treatment scheme with thermal pressure hydrolysis, struvite recovery and ammonium sulfate solution recovery in the WWTP Braunschweig–Steinhof has an additional cost as the fertilisers revenues are much lower than the additional annual infrastructure related costs, personnel and chemical costs. However, the nutrient recovery schemes are required to ensure that the discharge limits for nitrogen and phosphorus are met. Further LCC and CEA results can be found in D2.2.

Chemical risk assessment for the application of renewable fertilisers

In Braunschweig, phosphorus and nitrogen are recovered as struvite and ammonium sulphate solution for agricultural use. The risk was assessed for several inorganic substances (As, Cd, Cr, Cu, Pb, Hg, Ni, Zn), Benzo(a)pyrene and PCDD/F + dl‑PCB. No high risk was characterised for any of the secondary fertilizers with respect to the soil or groundwater ecosystem after long-term fertiliser application. Detailed results can be found in D2.1.

Legislation and policy recommendations

In NextGen, we analysed the policy and regulatory landscape to identify relevant opportunities for and barriers to upscaling circular economy in the water sector. Our recommendations, targeted at the revised Urban Wastewater Treatment Directive, are summarised in our policy brief. These recommendations focus on creating meaningful incentives and policy drivers towards circular systems (e.g., through energy and carbon neutrality targets, and additional guidance on water recycling) and simplifying the route to market for recovered products (e.g., fertilisers and other materials). More details can be found in our policy brief.

Important regulations for the Braunschweig case study are listed below. In addition, D1.5 provides an overview, how good the struvite and ammonium sulphate comply with the legal requirements.

- DüMV (2012) Verordnung über das Inverkehrbringen von Düngemitteln, Bodenhilfsstoffen, Kultursubstraten und Pflanzenhilfsmitteln (Düngemittelver-ordnung – DüMV vom 5. Dezember 2012, BGBl. I S. 2482), Bundesministerium der Justiz und Bundesamt für Justiz

- AbwV (2022) Verordnung über Anforderungen an das Einleiten von Abwasser in Gewässer (Abwasserverordnung – AbwV vom 17. Juni 2004 BGBl. I S.1108, 2625 und vom 20. Januar 2022 BGBl. I S. 87, Bundesministerium der Justiz und Bundesamt für Justiz

- EU (2019/1009) Regulation of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 20

- EU (2021/2086) Commission Delegated Regulation of 5 July 2021 amending Annexes II and IV to Regulation (EU) 2019/1009 of the European Parliament and of the Council for the purpose of adding precipitated phosphate salts and derivates as a component material category in E

Applied product

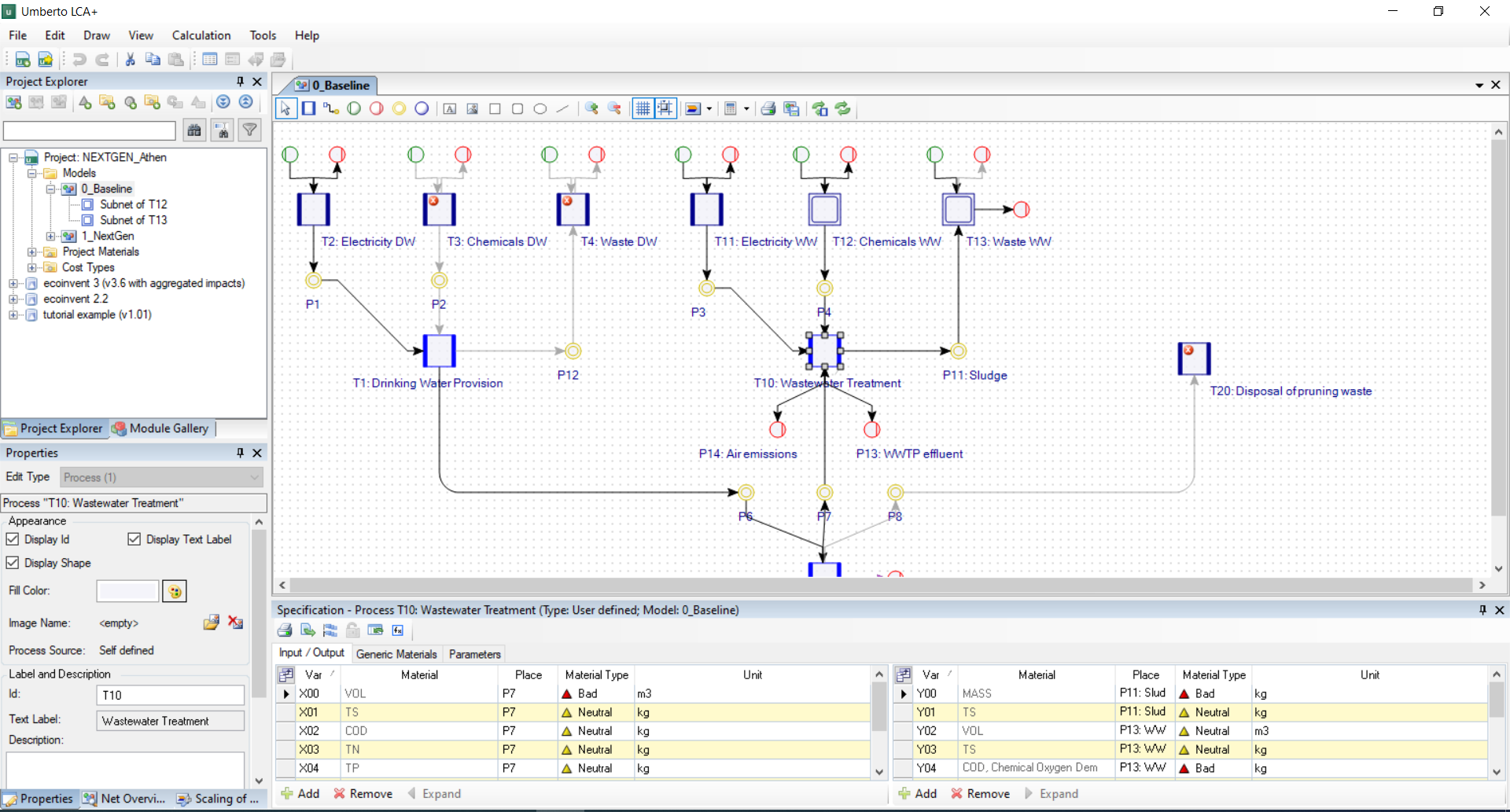

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…