Description

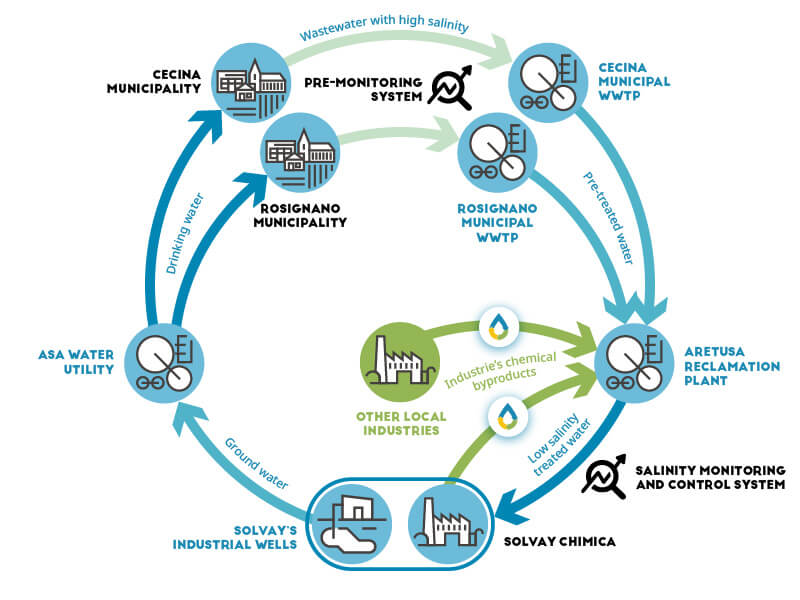

The ARETUSA Consortium has been established in 2001 and associates an urban water utility (ASA Azienda Servizi Ambientali Spa) in PPP with industry (Solvay Chimica Italia Spa) and technology provider (TME Termomeccanica Ecologia Spa). Thanks to ARETUSA water reclamation facility, Solvay replaces high-quality groundwater with fit-for-purpose treated municipal wastewater for industrial use, while groundwater is more exploited for drinking water production to serve the coastal areas. Up to 3.8 Mio. m³ per year of treated municipal wastewater is already reused by the industrial partner Solvay, freeing up Solvay private industrial wells for drinking water use. Currently, the Solvay plant has highly expanded both in terms of production and variety, which further increases the water demand. The plant produces sodium carbonate, sodium bicarbonate (also for pharmaceutical use), calcium chloride, chlorine, hydrochloric acid, chloromethane, plastic materials, peracetic acid and hydrogen peroxide. The ARETUSA water reclamation facility was designed to treat the secondary effluent coming from the two municipal Wastewater Treatment Plants (WWTP) of Cecina and Rosignano by chemical, physical, and biological processes in order to reach the quality requirements of Solvay. The catchments of Cecina and Rosignano WWTPs are impacted by currently unpredicted and relevant seawater intrusion that increases the chloride up to levels higher than acceptable and agreed by the contract in force among the ARETUSA partners. In addition, other parameters (e.g., surfactants and COD) can irregularly and unpredictably exceed the quality standard required for industrial reuse in Solvay. The successful results of ULTIMATE will be integrated in the definitive and executive design and implemented in full scale for real long-term operation. Three million euros investments to revamp, upgrade and digitalize the reclamation plant and system are currently envisaged by ARETUSA PPP.

Applied technologies

Technology performance and best practices

Early warning system for high chloride concentrations and smart equalisation system

In the Italian case study, the reuse of urban wastewater for industrial purposes requires low-salinity water. However, the area faces seawater intrusion into the sewer network. To mitigate this, a digital solution was proposed using a dynamic simulation model to predict salinity peaks in the sewer networks of the municipalities of Cecina and Rosignano and to allocate wastewater and reclaimed water to industrial, agricultural or specific treatments (e.g. reverse osmosis) to optimize reuse. The Stormwater Management Model (SWMM) effectively predicted the quantity and quality of seawater infiltrating the sewer networks and showed that the salinity of the wastewater exceeded the limits for industrial reuse. The smart equalisation system allowed a 19% discharge to reduce salinity by 23%, with 87% of the reclaimed water redirected to industry and 13% to agriculture. For agricultural reuse, crop tolerance to water conductivity was considered to determine appropriate reuse levels. As the equalisation system alone could not meet the quality standards for industrial reuse, a reverse osmosis (RO) system was piloted to successfully improve water quality.

Using by-products from industry in wastewater treatment

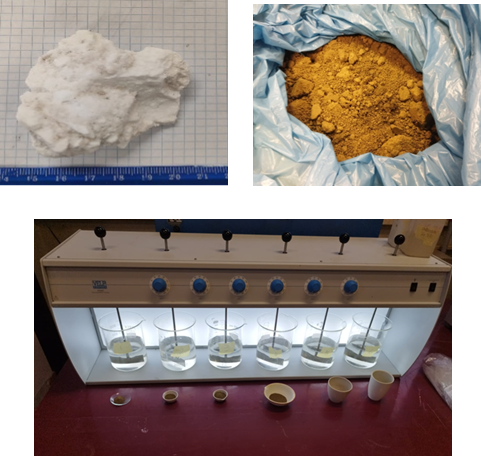

The Italian case study also investigated the possibility of using by-products from the industrial area of Rosignano (Livorno, Italy) as alternative materials to produce treated wastewater of suitable quality for industrial and agricultural reuse. The industrial by-products tested included bentonite, partially cooked limestone, off-specification soda ash, sewage sludge hydrochar, aluminum sludge, and H2O2 from the chemical industry. Successful pilot testing demonstrated the possibility of using off-specification soda as an alternative coagulant in the clariflocculation process with the advantage of simultaneous COD and hardness removal. Requirements for the use of out-of-specification soda in the coagulation process are continuous pH control and dosing in powder form.

Innovative real-time sensor

Furthermore, fluorescence probes were successfully tested as innovative real-time sensors to monitor the removal of organic micropollutants from wastewater during GAC adsorption processes and AOP (UV/H2O2) treatments. It was observed that the application of fluorescence sensors for micropollutant monitoring during quaternary treatments (i.e.; AOP, GAC filtration) required regular cleaning as well as installation in a location protected from sunlight to avoid interferences. Monitoring of adsorption processes required that the physical characteristics of the absorption system (i.e., carbon type, bed height) remain unchanged.

Outcome of assessments

Total cost of ownership (TCO)

The TCO assessment for the ARETUSA system, which manages treated wastewater for industrial processes, suggests that integrating the new system results in significant improvements in water quality, particularly by reducing salinity, which is crucial for its reuse in industrial applications. Over a 30-year period, the new system, despite requiring a capital investment of around 6.7 million EUR, considering the same quantities of water supplied to Solvay before the investment is projected to generate a profit of 15.2 million EUR. Nevertheless, the introduction of the new system enhances operational efficiency and water quality, increasing the volume of water supplied to Solvay and justifying the investment. Major cost items include operational costs, particularly electricity, with a significant portion of energy supplied at a favourable rate due to a pre-existing contract with Solvay. A sensitivity analysis shows that electricity prices as such have a limited impact on the TCO due to this contract, while interest rates on capital loans have a more pronounced effect, indicating that more favourable financial incentives could improve the technologies attractiveness.

Quantitative microbial risk assessment

The quantitative microbial risk analysis showed that there is a high potential of reusing the treated water for irrigation purposes in situation where conductivity is too high for industrial reuse. However, the lack of local validation data makes additional process validation necessary. For microbial parameters, the considered reverse osmosis unit is only an effective barrier if the complete volume stream is treated. A partial treatment has little to no effect on the final risk outcome.

Legislation and policy recommendations

Clarifying responsibilities and developing consistent guidelines for water reuse licensing and service provision across the EU are essential to ensure effective practices. The strategic agenda proposes comprehensive coverage of all water reuse types, emphasizing safety, environmental impact assessment, and the integration of reclaimed water into local water balances based on regional circumstances. Future regulations should establish minimum standards for non-agricultural uses, enhance risk assessment, and promote research on innovative water reuse technologies and practices. (see also D1.10)

Assess the opportunity of eco-labels and certification schemes for circular by-products. This may be an opportunity to foster material recovery purposes in Europe through the promotion of best practices to the consumers.