Description

The Symbiosis in Karmiel and Shafdan interconnects 2 SMEs from the agro-food sector with a public wastewater utility, linking an industrial wastewater treatment plant (WWTP) with a municipal WWTP. The agro-industrial sector includes agriculture, food industry, olive oil mills and water treatment. The symbiosis will enable to protect the current WWTP of Karmiel and Shafdan that are usually exposed to sudden shocks of strong and problematic agro-industrial wastewater (i.e, OMW, Slaughterhouse, winery). Karmiel municipal WWTP faces problems due to shock loads of olive mill wastewater (OMW) during the harvest period and due to illegal discharges from slaughterhouses in the area. No solution has been found yet for an upstream and on-site wastewater pre-treatment which is technically feasible, economically viable and socially acceptable. Thus, when happens, the wastewater is discharged without adequate treatment. Shafdan WWTP of Tel Aviv is Israel’s largest WWTP (400000 m³/d) and collects, treats and reclaims municipal wastewater in this rapidly growing area. Suitable pre-treatment of agro-industrial wastewater at the Shafdan site will enable the continuation of the current nature-based reuse system and supply water for agricultural activity in the Negev desert, even when receiving more agro-industrial wastewater in the future, in addition to paretially reduce the energy demand, decrease the sludge production as well as inccrese the biogas production.

Applied technology

Technology performance and best practices

Biogas production from anaerobic pre-treatment of olive mill wastewater

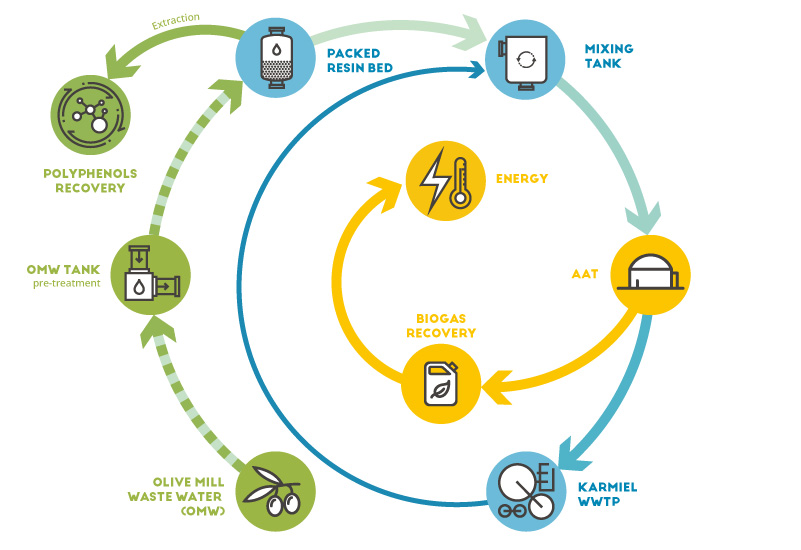

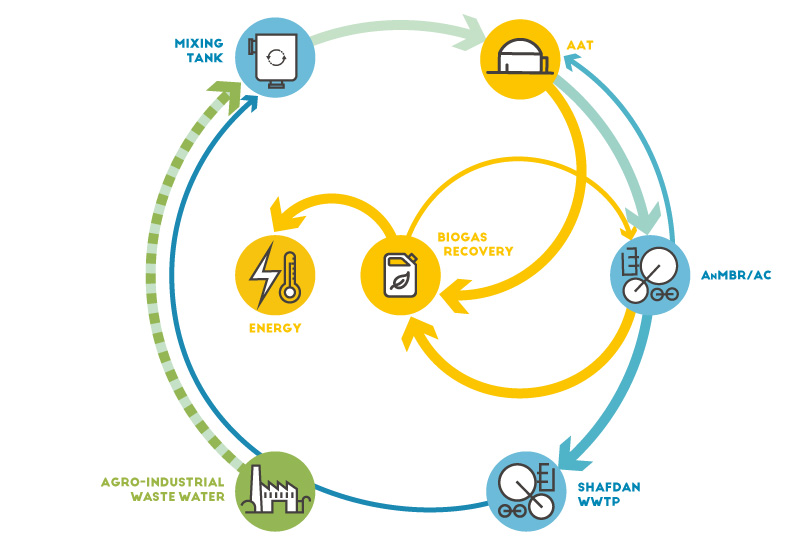

In the Israeli case study, another innovative anaerobic reactor was successfully tested for olive mill, winery, slaughterhouse and dairy effluents. In particular olive mill wastewater (OMW) contains a high fraction of polyphenols, which can lead to a microbial inhibition at certain concentrations. Removal of these inhibiting substances will significantly improve the treatability of the wastewater. In this case study, an innovative anaerobic immobilized high-rate reactor (AAT) was used as a stand-alone treatment and in a combination with activated carbon and an anaerobic membrane bioreactor. In Karmiel, a pilot AAT treated a mixture of municipal and OMW at an OLR of maximum 11 kg COD/(m³*d) with an OMW fraction of 2-3 kg COD/(m³*d) and a total flow rate of 100 m³/d. The COD removal rate was between 40% and 55%. An innovative combination of the AAT with an activated carbon treatment and an AnMBR was piloted at Shafdan. Laboratory experiments showed the successful treatment of agro-industrial wastewater with municipal wastewater (mWW). At a maximum OLR of 11 kg COD/(m³*d), 83-86% COD removal was achieved. Both systems successfully removed between 18-52% of the polyphenols. At the case study level, the anaerobic treatment systems have the potential to reduce the energy demand of the WWTPs by 20-50%.

Recovery of polyphenols from olive mill wastewater

In addition, ULTIMATE also tested the innovative VesperX adsorption/extraction system developed by Greener than Green Technologies (GtG) for the removal and recovery of polyphenols from olive mill wastewater (OMW) and as a pre-treatment for the subsequent anaerobic biological treatment process. Adsorption of polyphenols on the resin was followed by extraction of high value compounds as crude extract. An average reduction of 38% in the polyphenol content of the effluent was observed during the pilot tests. Even in this case, the critical factor for the implementation of the technology and its optimal performance and replicability on a large scale is the optimisation of capital expenditure (CapEx), which requires research and investment in cost-effective adsorption materials and advanced extraction methods.

Outcome of assessments

Total cost of ownership (TCO)

The TCO assessment for the AAT system, a high-rate anaerobic technology implemented as a retrofit at the Karmiel wastewater treatment plant, suggests that over a 20-year period, the system can generate a profit of approximately 2.5 million EUR. This is achieved through significant annual savings of up to 400,000 EUR in electricity costs and reduced sludge production, which lowers sludge transportation and treatment expenses. Major cost items include capital and maintenance, accounting for two-thirds of the TCO, primarily due to the production of the AAT matrix and associated civil engineering work. A sensitivity analysis shows that reducing the interest rate on borrowed capital could further improve the TCO, making the system even more financially sustainable.

Legislation and policy recommendations

To replicate biogas production and valorisation technologies, stable prices for upgraded biogas and electricity are needed at least for a period of five years to amortise the plant. Another five years would be beneficial, after an adaption on the energy market, to provide incentives to the investors. To bridge a potential gap between the guaranteed price and the actual market price, subsidies might be needed. A minimum quota for upgraded bio-methane in the gas grid can further support the willingness of investors to implement biogas production technologies and upgrading units. A simplification of administrative formalities and financial support related to the gas grid connection can highly accelerate the implementation of biomethane producing technologies. (see also D1.10)