Description

The Roches-Roussillon chemical platform exists since 1915 and brings together 16 companies specialised in the chemical industry on the same site, including several giants of the sector such as Seqens, Elkem and Adisseo. SUEZ RR IWS Chemicals operate on this platform two hazardous waste incinerators that treat a significant proportion of the chemical platform waste and a biomass recovery unit that provides 15% of the chemical platform steam requirement. On Roches-Roussillon site, SUEZ RR IWS CHEMICALS activity focuses on three areas:

1) Aqueris: high temperature incineration of industrial liquid hazardous waste (aqueous and organic), specialised in:

- Aqueous waste with strong salt content

- Sulphurous waste (mercaptan type)

- Very dangerous waste (cyanide, acetonitrile, etc.)

2) Aqueris: evapo-incineration, for waste with a low pollutant load

3) Robin: hazardous and non-hazardous biomass valorisation, with steam production distributed to the platform industrials.

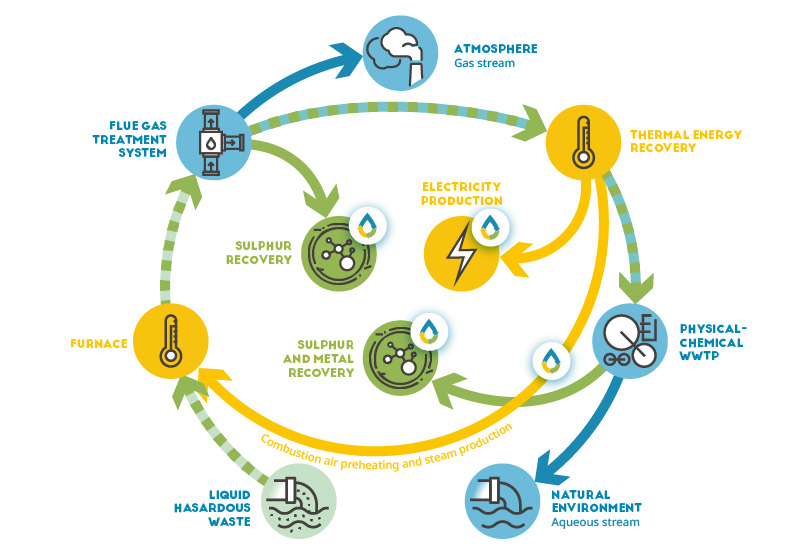

Among these, the Ultimate project will be involved in the Aqueris application. Over the past five years, the site has developed the ranges of waste received with the treatment of high-sulphur waste. This has resulted in an increase in the amount of sulphates collected in the washing water and then sent without recovery to the treatment plant. Due to environmental constraints (discharge of sulphate in the Rhône must be below 26 g/L and 24 t/d, sulphur dioxide content in the fumes must be lower than 120 mg/Nm3/30min and 30mg/Nm3/day), but above all due to the will of SUEZ to convert Aqueris into a material recovery unit, a project is being studied by the Industrial Department of SUEZ RR IWS for the recovery of sulphur.

The three technical-economic feasibility studies are carried out by IWS using data (site measurements and calculated indicators) configured and available in the ULTIMATE IT application, based on the WASTE ADVANCED® Data Management software product (formerly AQUACALC™), developed by 3S.

Applied technology

Technology performance and best practices

Sulphur recovery

At the Chemical Platform Roussillon in France, the recovery of sulphur from the flue gas of a hazardous waste incinerator was tested in a pilot demonstration under real conditions with different process steps, including condensation, dust removal and scrubbing, in order to reduce the pollutant load in the water from the flue gas cleaning. The aim of the process was to produce sodium bisulphite (NaHSO3) solution from the sulphur dioxide contained in the flue gas from the incinerator. The treatment system, which still has room for improvement, was able to recover 80% of the organic sulphur waste. In particular, improvements can be achieved by treating the flue gas upstream of the sulphur recovery unit, which ensures effective cleaning of dust and salts and preserves the sulphur dioxide concentration. The key factors for scaling up and replicating the system on a large scale are: i) contractualisation for the management of the upstream organic sulphur waste and the downstream sodium hydrogen sulphite; ii) regulations and research grants to further promote the development of the recovery treatment system.

Outcome of assessments

Feasibility study: recovery of molybdenum

This case study also included a feasibility study for the recovery of molybdenum from flue gas washing water. The study was based on laboratory tests where different ion exchange resins were investigated for their molybdenum adsorption capacity and their ability to recover molybdenum during the elution stage. The results showed the possibility of achieving >99% adsorption yield and, under optimal conditions, elution yield in the range of 66-87%. In order to scale up the treatment process, recommendations relate to the identification of the most suitable and economical resin for the metal to be recovered, allowing both effective adsorption from the aqueous effluent and effective elution to produce a recoverable solution.

Feasibility study: recovery and reuse of heat

The French case study also investigated the reuse of heat from an incineration process at a hazardous waste incinerator to produce electricity using the Organic Rankine Cycle (ORC) or to produce steam using a heat pump. Neither option proved to be technically or economically feasible. Either the residual heat recovery rates were below the target of 25% or the steam production would have to be on such a large scale that the capacity of the existing technical system would be too small. In addition, the expected revenue from electricity or steam sales was not sufficient to reach the break-even point. For the ORC process, the profit was estimated at 256 k€/a. However, taking into account the level of depreciation and the minimum operating and maintenance costs for this type of plant, a turnover of 600 k€/a is the minimum to reach the break-even point. For the heat pump process, a minimum turnover of 6 M€/a is required to reach the break-even point, while the expected profit from the sale of steam was estimated at 4 M€/a. In parallel with the feasibility studies, an application for data monitoring and analysis was developed and successfully tested. This application was designed to be easily adaptable to other heat recovery concepts and to serve as a basis for future concepts.

The French feasibility study showed that minimising the distances between the systems to avoid heat losses and maximise the benefits of increased temperature in each system had a very large impact on the feasibility of the concepts. In addition, pipe and system insulation was critical to avoid losses even in colder climates and a carbon impact assessment was necessary to assess its overall carbon footprint.