Unique selling points

- High recovery percentages (highest yield on COD about 50%)

- Recovered nutrients as single cell proteins with high quality which can be used as slow-release fertiliser and potentially fish fodder

Microalgae and purple phototrophic bacteria production from wastewater that can be used as fertilizer

Capacity

Pilot-scale 60 L/day

Description of the technology

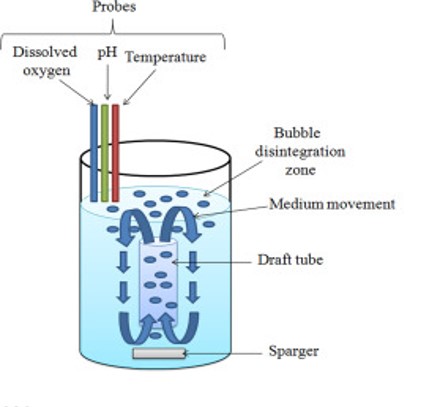

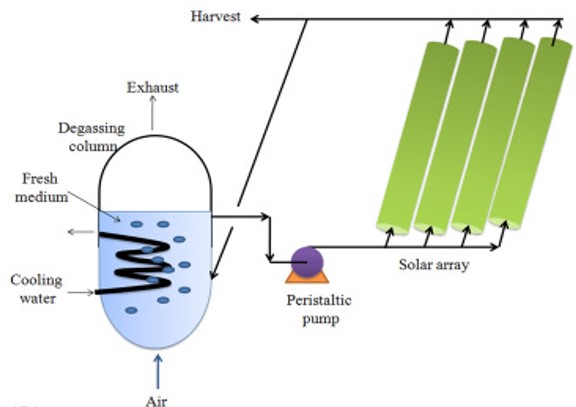

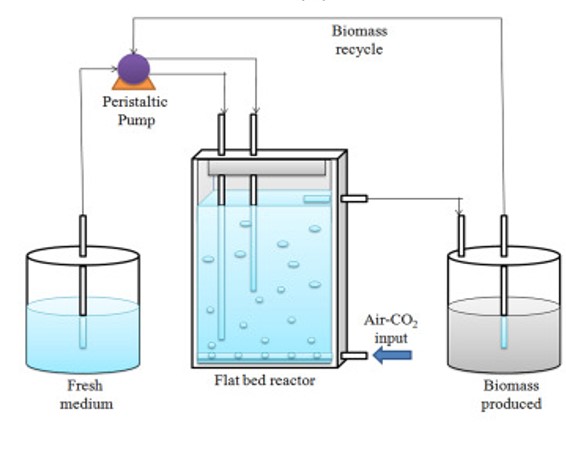

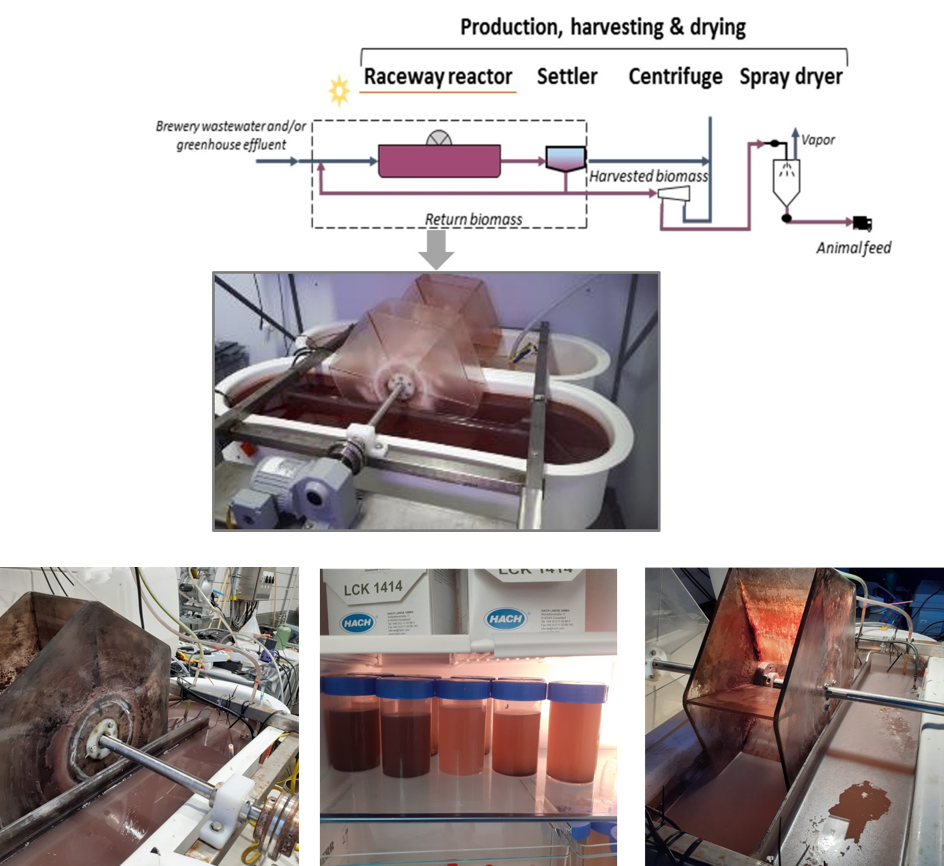

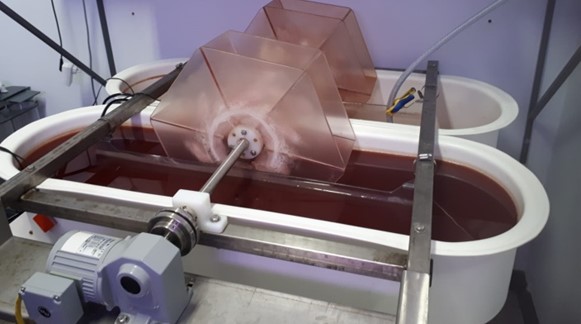

Photobioreactors (PBR) act as solar receivers and supply sunlight (visible) and carbon dioxide (CO2) to microalgae (MA). Purple phototrophic bacteria (PPB) are heterotrophic and need much smaller quantities of CO2 and sunlight (Infrared) and are therefore more suitable for cultivation on brewery water. MA and PPB can remove and recover nutrients from wastewater effluents that can be used as bio-fertilizer and organic fertilizer used to produce target products and potentially fish fodder. Light and CO2 are used as the energy source and the inorganic carbon source, respectively. A typical PBR system consists of three phase systems: liquid phase (i.e. medium), solid phase (i.e. cell growth), and gaseous phase. In general, there two major types: open and closed systems. As shown in Flow scheme of the technology, open PBR systems include raceway ponds and circular ponds, while closed PBR systems include tubular reactors, flat-plate reactors, annular reactors, and fermenters (Mishra, Kaushik, & Tiwari, 2019). Open systems are more favourable due to cost considerations, but it may also reduce the quality of the produced biomass. The determination of the design of PBRs highly depends on the desired end-product in the cultivated biomass and the quality of the target products. In addition, the following design parameters must be considered: gas transfer, mixing pattern, contamination control, photosynthetic efficiency (sunlight or an artificial light source), building material, and geometrical configuration.

Flow scheme of the technology

|

(A)

|

|

(B)

|

|

(C)

|

|

Types of photobioreactor systems; (A) vertical column reactor, (B) tubular photobioreactor and (C) flat-bed photobioreactor (Mishra et al., 2019). |

Pictures

Synergetic effects and motivation for the implementation of the technology

- Develop ecosystem services/businesses

Cultivating and harvesting nutrients from wastewater would lead to increasing commercial interest in their use for producing valuable substances for animal and human food, as well as for mitigation of greenhouse gas emissions in the environment. In view of potential applications, PBR applications can play an important role within the new circular economy by shifting the conventional resource recovery scheme towards a more eco-friendly scheme.

- Resource recovery from RO brine and provide economic/environmental benefits

Typically, RO brine contains a high concentration of organic and inorganic compounds (e.g. nitrates, sulphates, or organic molecules). Brine management is one of the important factors for RO facilities as it offers the opportunity to reduce brine disposal costs while simultaneously producing more treated water. The recovery of the valuable contaminants in the RO concentrate is one of the promising options for brine management. The recovered materials can be converted into fertiliser that can be sold and thus raise the profits of a water treatment plant.

Technology requirements and operating conditions

Major factors affecting PBR efficiency include light energy, pH, temperature, carbon dioxide enrichment, oxygen removal and mixing. It is important to maintain the optimal light condition during cell cultivation as the utilisation of light energy can significantly influence the algal culture and thus algal growth rates. In terms of pH and temperature, the increasing CO2 concentration would drop the pH and this will dramatically damage the cells. The change of the culture temperature also influences the overall productivity. For example, the algae in outdoor PBRs are exposed to seasonal variations, temperature and light intensity. These indicate that inhibition of cell growth rates is attributed to pH and temperature changes during cell cultivation. In order to prevent this issue, buffered medium or installation of a pH-stat system coupled with PBRs can be considered. In addition, high oxygen concentration can also inhibit algal growth, even at high concentrations of CO2. To decrease or remove the O2 tension in the culture, the installation of a degassing system on PBR systems can be considered. Finally, it is important to maintain continuous mixing of an algal suspension to keep the cell in suspension, to enhance light supply efficiency, to improve gas exchange, to eliminate thermal stratification, and to help nutrient supply. The degree of mixing has a significant effect on algal productivity.

General data

|

Parameter |

Units |

Min |

Max |

Reference |

|

pH |

- |

7 |

8 |

|

|

DO |

mgO2/L |

0.2 |

0.5 |

Alloul, Cerruti, Adamczyka, Weissbrodt, and Vlaeminck (2020) |

|

Temperature |

°C |

Ambient |

||

Key performance indicators

|

Parameter |

Units |

Average |

Reference |

|

COD |

g/L |

5 |

|

|

TN |

g/L |

0.3 |

|

|

Bacterial product |

g/L/day CODbiomass |

Max 2.5 at OLR of 5 gCOD/L*d |

NextGen D1.5 (in prep.) |

Links to related topics and similar reference projects

|

Nutrients recovery technology |

Reference |

|

ESA's life support system R&D program |

Case Study applying the technology

Publications

- Alloul, A., Cerruti, M., Adamczyka, D., Weissbrodt, D. G., & Vlaeminck, S. E., Control tools to selectively produce purple bacteria for microbial protein in raceway reactors, 2018

- Kleyböcker, A., Kenyeres, I., Poor-Pocsi, E., Nättorp, A., Loreggian, L., Schaub, M., Egli, C., Grozavescu, M., Murariu, M., Radu, B., Scheer, P., Lindeboom, R., Giurgiu, R., Suters, R., Heinze, J., Soares, A., Vale, P., Kim, J., Lanham, A., Hofman, J., D1.5 (2022) New approaches and best practices for closing materials cycle in the water sector, 2022

- Mishra, A. K., Kaushik, M. S., & Tiwari, D., Nitrogenase and Hydrogenase: Enzymes for Nitrogen Fixation and Hydrogen Production in Cyanobacteria, 2019