Unique selling points

- Tailor made rejection yields (e.g. > 80% of emerging pollutants/priority substances; > 99% of microorganisms; > 95% of salts).

- Reuse of a waste (end-of-life RO membranes) that is regenerated (regenerated RO membranes) and can be used in the water cycle.

- To produce a regenerated water with enough quality to be reused.

Description of the technology

Ultrafiltration (UF) and nanofiltration (NF) are membrane filtration processes whose purpose is to remove mainly suspended solids and organic matter and divalent ions from liquid effluents, respectively. They normally work at pressures of 1-5 bar (UF) (Jafarinejad, 2017) and 5-20 bar (NF) (Charcosset, 2012) and present zero or low monovalent ions rejection, respectively.

In general terms, UF process is able to efficiently separate colloidal particles, viruses and bacteria (Spivakov and Shkinev 2005), but has low salt rejection (Calabrò and Basile 2011). On the other hand, NF not only enables the separation of even smaller organic molecules, but also of inorganic salts. However, it is to note that NF membranes have low rejection of monovalent ions, high rejection of divalent ions and higher permeabilities compared to RO membranes (Wu et al., 2017).

As a function of the oxidation degree, regenerated end-of-life reverse osmosis (RO) membranes can operate as UF and NF modules. By this way, a waste can be reused in the water cycle, incrementing their lifetime.

In the NextGen project, a pilot plant located in the wastewater treatment plant (WWTP) of Tossa de Mar is integrated by an UF module coupled successively to a NF one, both fitted with regenerated RO membranes.

The demonstrated flowrate capacity production of the pilot plant is of 2 m3/h.

Flow scheme of the technology

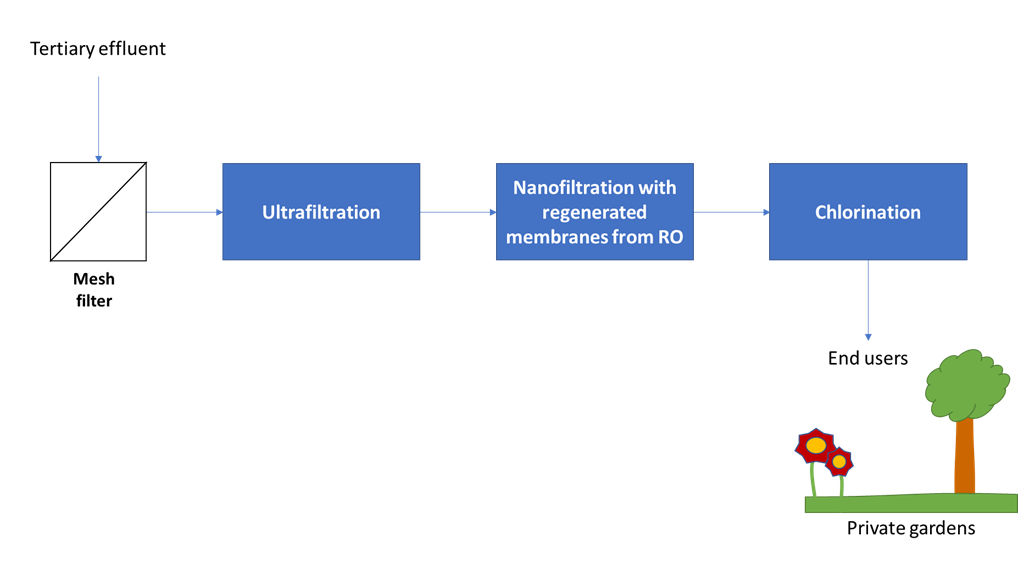

The simplified scheme diagram of the process is shown in Figure 1.

Figure 1. Simplified scheme of the NextGen pilot plant where UF and NF with RO regenerated is implemented (Costa Brava case study, Catalonia).

Pictures

Synergetic effects and motivation for the implementation of the technology

- Establishment of a circular economy concept (by the reuse of membranes).

The valorisation of the RO end-of-life membranes is a key aspect to establish the circular economy practices in the water cycle.

By this way, a waste (RO end-of-life membranes) can be regenerated (through an oxidation step) and later can be reused in the NF or UF modules as a function of oxidation degree. Therefore, this practice increases the circularity in the water process.

- Reduction of the emerging/priority pollutants that reach aquatic systems.

By removing emerging/priority pollutants from the wastewater treatment plants (WWTP) effluents, NextGen will contribute to avoiding that certain organic substances reach aquatic systems thus preventing certain effects on the fauna related to endocrine disrupting process as well as protecting the flora. Furthermore, high quality water can be suitable to recharge the aquifers and, consequently, to be used for indirect potable reuse (IPR).

- Reduction of the drinking water consumption destined to private garden irrigation.

UF & NF processes fitted with regenerated RO membranes will produce a regenerated effluent the quality of which allowing to use it for the private garden irrigation. This fact will contribute to reduce the quantity of drinking water consumed for this application, therefore improving the availability of this resource.

Technology requirements and operating conditions

A mesh filter must be incorporated at the beginning of the treatment to ensure that any coarse solid reaches the UF module.

Cleaning cycles of UF & NF processes should be performed periodically to ensure suitable operation.

The following table summarize the most appropriated values of several parameters for the conventional UF & NF processes (which would be different when working with regenerated RO membranes).

Table 1. Required specifications for the UF and NF systems.

|

UF |

||||

|

Parameter |

Units |

Min |

Max |

Reference |

|

Transmembrane pressure (TMP) |

bar |

- |

2.1 |

|

|

Temperature |

ºC |

1 |

40 |

DuPont, 2019 |

|

pH |

upH |

2 |

11 |

DuPont, 2019 |

|

Particle size |

µm |

0.03 |

0.5 |

Spivakov and Shkinev 2005 |

|

|

||||

|

NF |

||||

|

Parameter |

Units |

Min |

Max |

Reference |

|

Turbidity |

NTU |

>1 |

>1 |

NextGen D1.2 |

|

Pressure |

atm |

5 |

50 |

Cheremisinoff, 2001 |

|

Temperature |

ºC |

1 |

45 |

NextGen D1.2 |

|

pH |

- |

2 |

11 |

NextGen D1.2 |

|

SDI |

- |

|

5 |

DuPont, 2020 |

|

MFI0.45 |

- |

|

4 |

DuPont, 2020 |

|

Oil and grease |

mg/L |

|

0.1 |

DuPont, 2020 |

|

TOC |

mg/L |

|

3 |

DuPont, 2020 |

|

COD |

mg/L |

|

10 |

DuPont, 2020 |

|

AOC |

µg/L Ac-C |

|

10 |

DuPont, 2020 |

|

BFR |

pg/cm2 ATP |

|

5 |

DuPont, 2020 |

|

Free chlorine |

mg/L |

|

0.1 |

DuPont, 2020 |

|

Ferrous iron |

mg/L |

|

4 |

DuPont, 2020 |

|

Ferric iron |

mg/L |

|

0.005 |

DuPont, 2020 |

|

Manganese |

mg/L |

|

0.005 |

DuPont, 2020 |

|

Aluminium |

mg/L |

|

0.005 |

DuPont, 2020 |

Key performance indicators

The KPIs to be monitored during the UF and NF processes, specifically those related with Costa Brava case study are summarized in the following table.

Table 2. KPIs for the coupling of UF and NF processes fitted with RO regenerated membranes in the Costa Brava case study.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Water yield of the system |

% regenerated water produced |

40 |

80 |

NextGen, D1.2 |

|

Salt rejection yield |

% salt removal |

80 |

> 97 |

NextGen, D1.2 |

|

Global removal yield for several priority / emerging pollutants |

% pollutants removal |

40 |

>99.9 |

NextGen, D1.2 |

|

TSS and turbidity removal yield vs inlet flow to the system |

% |

85 |

99 |

NextGen, D1.2 |

|

E. coli final effluent concentration |

CFU/100mL |

<LOD |

0 |

Spanish legislation in water reuse (RD 1620/2007) |

|

Intestinal nematodes final effluent concentration |

Egg/L |

<LOD |

1 |

|

|

Legionella spp. final effluent concentration |

CFU/L |

<LOD |

100 |

|

|

Electricity consumption |

kWh/m3 water |

Mean value: 2 kWh/m3 |

Garcia-Ivars et al., 2017 | |

|

Flux related to transmembrane pressure |

L m-2 h-1/bar |

Mean Value: 13 LMH/bar |

Garcia-Ivars et al., 2017 | |

Links to related topics and similar reference projects

|

UF & NF with regenerated RO membranes |

Reference |

|

NextGen |

|

|

DEMOWARE |

UF & NF with conventional membranes applied for IPR in the Port de la Selva (Costa Brava, Spain). |

|

ZEROBRINE |

Deliverable D4.2 Regeneration and performance of reverse osmosis membranes from desalination plants. |

|

SUGGEREIX |

Link to the emerging/priority substances analysed in water in the Costa Brava region. |

Case Studies applying the technology

Publications

- Calabrò, V. and Basile, A., Fundamental membrane processes, science and engineering., 2011

- Charcosset, C., Some perspectives. In Charcosset C. Membrane process in biotechnology and pharmaceutics, 2012

- DuPont™, Water solutions: FilmTec™ Reverse Osmosis Membranes Technical Manual, 2020

- DuPont™, IntegraPac™ Ultrafiltration Module and Skid Product Manual., 2019

- Garcia-Ivars, J. Martella, L., Massella, M. Carbonell-Alcaina, C. Alcaina-Miranda, M. I., Iborra-Clar, M. I., Nanofiltration as tertiary treatment method for removing trace pharmaceutically active compounds in wastewater from wastewater treatment plants., 2017

- Jafarinejad, S., Treatment of oily wastewater. In Jafarinejad S. Petroleum waste treatment and pollution control, 2017

- Plana Puig, Q., Nanu, C., Groza, I., Soares, A., Vale, P., Monokrousou, K., Makropoulos, C., Katsouras, G., Tsalas, N., Tazes, N., Tsimnadis, K., Lindeboom, R., Plata, C., Suters, R., Kenyeres, I., Plà, M., Filipsson, S., Hedman, F., Kim, J., Hofman, J.,, D1.3 New approaches and best practices for closing the water cycle, 2022

- Spivakov, B. and Shkinev, V., Membrane techniques: Ultrafiltration. In Worsfold, P., Townshend, A. and Poole, C. Encyclopedia of Analytical Science, 2005

- Wu, L., Wang, H., Xu, T.-W. and Xu, Z.-L., Polymeric membranes. In Jiang, L.Y. and Li N. Membrane-based separations in metallurgy. Principles and Applications, 2016