Unique selling points

- High removal percentage from water of recalcitrant organic compounds (such as emerging pollutants or priority substances) (higher than 95%) and microorganisms (higher than 99.9%).

- Reagents are in-situ generated through UV irradiation and oxygen or air pumping through ozone generator.

Description of the technology

Ozonation is an Advanced Oxidation Process (AOP) based on the ozone gas generation and its dissolution into the polluted water. Ozone is a powerful oxidant able to degrade or mineralize organic matter. When the process is carried out at neutral or acidic pH, the ozone selectively attacks certain organic substances, whereas at pH= 9 or higher, hydroxyl radical (●OH) is generated. Hydroxyl radical is one of the most powerful oxidant species, which has the capacity to non-selectively degrade, or also mineralize, different types of organic matter.

When combined with UV, simultaneously or successively, the dissolved ozone molecules absorb UV light with a peak absorbance of 260 nm and a molar absorptivity of 3292 ± 70 M/cm (Hart et al., 1983), thus making ozone undergo photolysis reactions to yield hydrogen peroxide (Beltrán, 2004).

The combined UV and ozonation can produce a larger quantity of hydroxyl radicals and other reactive oxygen species (ROS), which are able to attack organic matter, than working separately; moreover, UV/O3 can produce the photolysis of certain organic compounds and can also cause microorganism damage and therefore lead to their subsequent inactivation. However, not all photo-assisted processes require the same wavelength and energy to reach their optimal performance (Bajpai, 2017).

In the NextGen project, ozonation process combined simultaneously with UV (UV/O3) is applied to disinfect and to remove certain trace organic compounds (TrOCs) from water such as some plant protection products (PPPs) before all the horticulture water streams were reused in the greenhouses (according to the Netherlands legislation that obliges to the zero PPPs emission).

NextGen’s pilot plant have a capacity of 500 m3/ha/ year

Flow scheme of the technology

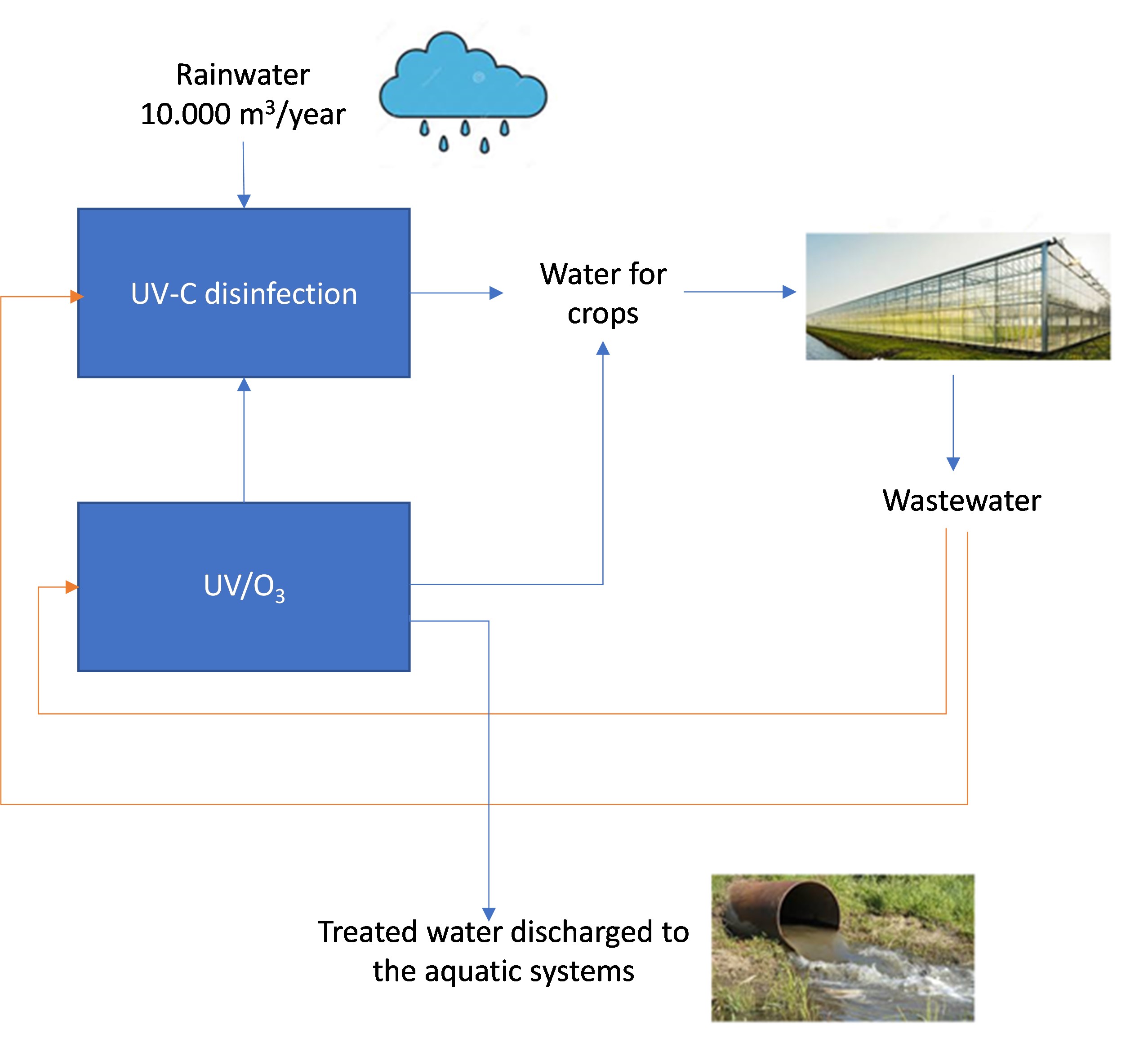

Scheme of the circular water scheme in the horticulture of the Westland region where an UV/ozonation technology is used.

Figure 1. Flow scheme for UV/Ozone in Westland case study.

Pictures

Synergetic effects and motivation for the implementation of the technology

- Reduction of the emerging/priority pollutants (TrOCs) that reach aquatic systems.

By removing plant protection products (PPPs) or other emerging/priority substances from the horticulture streams (or other type of wastewater) and by recycling part of them in the greenhouses, NextGen will contribute to avoiding that certain organic substances reach aquatic systems thus preventing certain effects on the fauna related to endocrine disrupting process as well as protecting the flora.

- Reduction of the drinking water consumption destined to irrigation.

UV/O3 will remove organic pollutants and disinfect the horticulture wastewater. Therefore, it will allow to produce regenerated water to be used for irrigation purposed in the greenhouses to focus on zero PPPS discharge legislation. This will contribute to reduce the quantity of drinking water consumed for this application, therefore improving the availability of this resource.

Technology requirements and operating conditions

A mesh filter must be incorporated at the beginning of the treatment to ensure that any coarse solid reaches the AOP treatment. Turbidity values in the influent higher than 20 NTUs indicate that a pre-treatment is needed. Otherwise, the UV/O3 will destroy part of the suspended solids and redissolve them, implying an increase on dissolved organic content of the water.

The following table summarize the most appropriated values of several parameters.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Turbidity |

NTU |

0 |

20 |

The presence of the suspended solids significantly affects the effluent optical properties, mainly the UV radiation transmission. (Mierzwa et al., 2018) |

|

Ozone concentration |

mg O3/l |

10 |

50 |

“Further increase in ozone dosage slightly increased the removal rate of pollutants, but the effect was very limited” (Rekhate and Srivastava, 2020). |

|

pH |

- |

8 |

10 |

Although it can be performed at all the pH range, it is preferable basic pH to promote the ozone destruction to hydroxyl radical (Rekhate and Srivastava, 2020). |

|

UV wavelength |

nm |

100 |

400 |

A wavelength of 254 nm is the most effective (Summerfelt, 2003). |

Temperature is also a key parameter during UV/O3 process. At higher temperature, higher the organic removal is; whereas as lower the temperature is, higher the ozone solubility. The combination of these opposite effects is different for every water to be treated; therefore, the temperature effect must be specifically studied in every case study.

Key performance indicators

The specific KPIs for the UV/O3 system during NextGen project is detailed in the following table.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Degradation of specific TrOCs |

% |

< 10 |

100 |

|

|

Global removal yield of organic matter |

% of DOC removed |

< 10 |

> 90 |

High variability depending on the conditions. |

|

Ozone concentration |

mg O3/l |

10 |

50 |

Rekhate and Srivastava, 2020 |

Links to related topics and similar reference projects

|

UV/O3 |

Reference |

|

NextGen |

Case Studies applying the technology

Publications

- Bajpai, P., Chapter 7 - Emerging Technologies for Wastewater Treatment. In: Bajpai, P (Ed.). Pulp and Paper Industry., 2017

- Beltrán, F. J., Ozone reaction kinetics for water and wastewater systems, 2004

- Hart, E. J., Sehested, K. and Holoman, J., Molar absorptivities of ultraviolet and visible bands of ozone in aqueous solutions, 1983

- Plana Puig, Q., Nanu, C., Groza, I., Soares, A., Vale, P., Monokrousou, K., Makropoulos, C., Katsouras, G., Tsalas, N., Tazes, N., Tsimnadis, K., Lindeboom, R., Plata, C., Suters, R., Kenyeres, I., Plà, M., Filipsson, S., Hedman, F., Kim, J., Hofman, J.,, D1.3 New approaches and best practices for closing the water cycle, 2022

- Rekhate, C. V and Srivastava, J.K., Recent advances in ozone-based advanced oxidation processes for treatment of wastewater- A review, 2020

- Summerfelt, S. T., Ozonation and UV irradiation - an introduction and examples of current applications, 2003