Unique selling points

- Achieves regulation compliance (organic matter, nitrogen, and more)

- Enables new treatment solutions

- Improves efficacy of treatment facilities without a significant investment in infrastructure

- Enhance existing platforms

- User pays per treatment (not for infrastructure)

Description of the technology

The bioaugmentation treatment approach presents both an economical and environmentally friendly solution for wastewater treatment. However, the use of exogenous bacterial cultures presents several limitations: negative interaction between microorganisms and adaptation to new physical and chemical composite environment. These selective forces create a significant challenge for the introduced culture to achieving the required biomass in order to conduct the

the target biological treatment (Menashe & Kurzbaum, 2014).

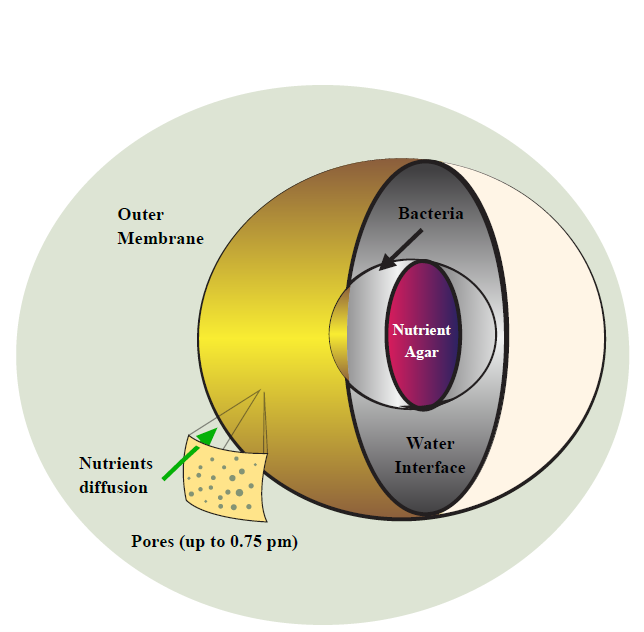

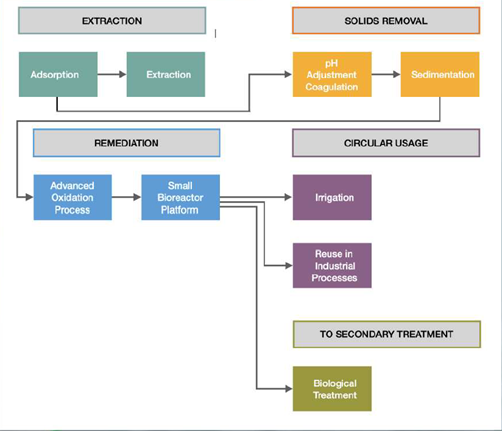

The Small Bioreactor Platform (SBP) technology (Menashe & Kurzbaum, 2013a) is an innovative patented technology (US Patent No. US 8,673,606 B2/Europe Patent No. EP 2421544/Australia Patent No. 2010240486 / Israel Patent No. 213072) integrating engineering and microbiology into a solution that enables us to adapt and accomplish a sufficient biomass of selective bacterial cultures. The SBP capsules (approx. 2.5 cm in length) are coated with a semi-permeable membrane (micro-filtration) which only allows dissolved molecules and compounds to traverse across the membrane, while keeping the microorganisms inside with favourable micro-cosmos conditions for weeks.

The physical barrier provides the exogenous bacterial culture protection from culture dilution and negative interactions with outer microorganisms, i.e protozoa. As a result, a significant reduction in the natural selection forces against the introduced culture is achieved, allowing the rapid growth of sufficient selective biomass. The SBP capsules are integrated inside the wastewater treatment plant bioreactor (host bioreactor) by using introduction devices.

Figure: Small Bioreactor Platform capsule design: the patented technology enables to introduced selective microorganisms’ culture to various types of water bodies to perform their biological cleaning processes.

Flow scheme of the technology

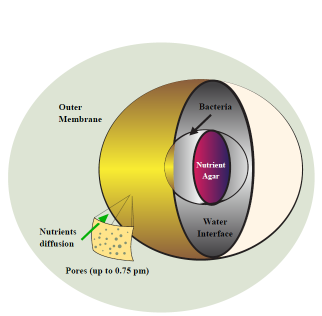

In the framework of the ULTIMATE project, in the Work Package 1, SPB is applied to treat the fruit processing water by-product. The industrial by-product goes through several treatment steps (filtration, coagulation, AOP) and end-up in a tank where SPB capsules are in place.

The aim of the overall process is to valorise the water and use it for agriculture and secondary uses and the aim of the SBP platform step, specifically, is to further degrade organic molecules surviving the AOP.

Figure: Flow diagram of the process

Bioaugmentation treatments in general and the use of encapsulated selected microbial cultures in particular are gaining significant attention as a promising approach for the treatment of wastewater containing phenols and other organic pollutants (Kurzbaum et. al., 2020).

Figure: Illustrations of a bioreactor bioaugmented with a P. putida culture encapsulated within small bioreactor platform (SBP) capsules. (a) An intact/cut SBP capsule. (b) Schematic illustration of the SBP capsule’s microfiltration membrane. (c) Schematic diagram of a continuous bioreactor treatment process using the SBP technology to treat phenol (Kurzbaum et al., 2020b).

Synergetic effects and motivation for the implementation of the technology

- SPB can be used as a wastewater additive treatment

Due to the membrane film that separates the microorganisms, SPB allows the implementation of exogenous bacterial culture (bioaugmentation) within a host bioreactor thus allowing us to enhance a specific culture or to create a microbial blend. This addition improves the performance of the bioreactor and increases the stability under stressful incidents (Menashe & Kurzbaum, 2013b).

Technology requirements and operating conditions

The SBP technology in the ULTIMATE case study 4 is used as a standalone treatment step and requires relative steady flow and content, dissolved oxygen higher than 1mg/L and pH around 7.

The SBP technology in the ULTIMATE case study 4 is used as a standalone treatment step and requires relative steady flow and content, dissolved oxygen higher than 1mg/L and pH around 7.

Table 1. Small bioreactor platform operation conditions

|

Parameter |

Range |

Reference |

|

Phenol concentration |

25-1000 mg/L |

|

|

Hydraulic retention time |

0,25-7 h |

|

|

Temperature |

30-36ºC |

|

|

Inlet flow rate |

21-640 mL/h |

Key performance indicators

Table 2. Small bioreactor platform KPI

|

Parameter |

Unit |

Reference |

|

Biodegradation rate |

5,7-90 mg/L/h |

Links to related topics and similar reference projects

|

Process/technologies |

Reference |

|

Phenol biodegradation |

(Kurzbaum et al., 2020) |

|

Olive wastewater treatment |