Description

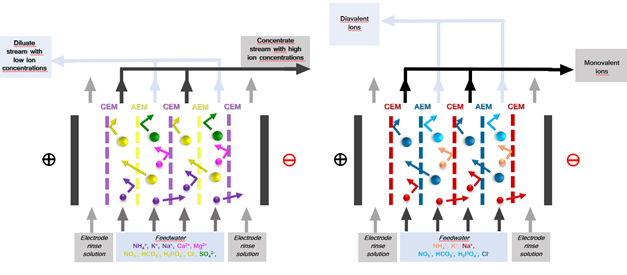

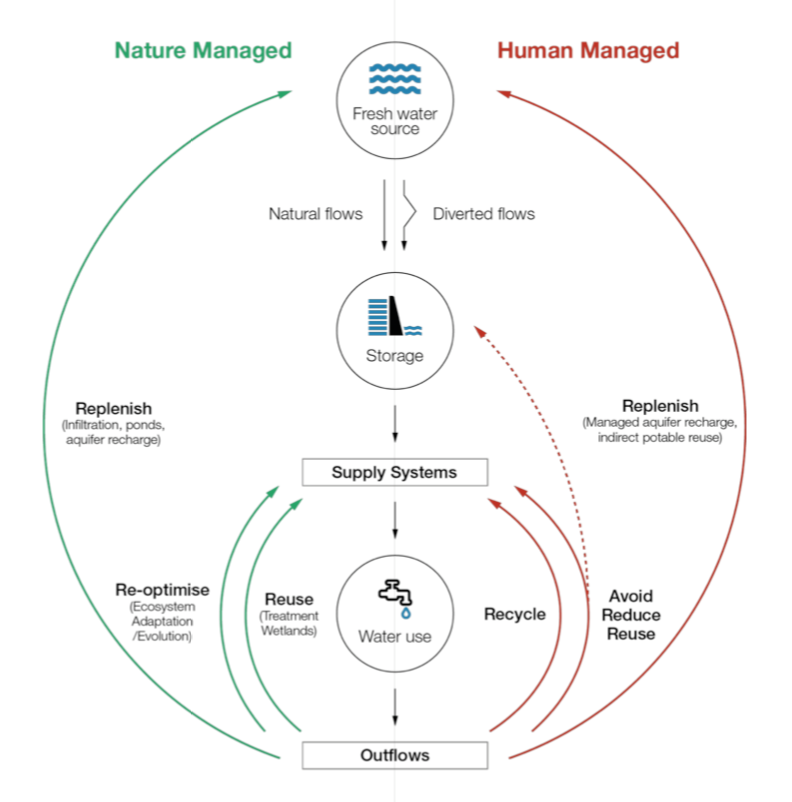

The Dow Boehlen plant, located south of Leipzig, Germany, operates in a water-scarce region, making efficient water management a priority. This case study focuses on reducing freshwater intake by enhancing internal water recycling and implementing a smart-monitoring system to optimize and automate water source selection. The project addresses four key water streams: optimizing cooling tower make-up water intake, improving treatment for pre-decarbonized water from the raw water treatment plant, investigating direct reuse options for cooling tower blowdown, and testing treatment technologies for reusing effluent from the industrial wastewater treatment plant on site. A combination of advanced technologies is employed through 3 test scenarios, including flocculation, membrane filtration (ultrafiltration, nanofiltration, reverse osmosis), ion exchange, advanced oxidation (UV-H₂O₂, ozone), electrocoagulation, and activated carbon filtration. Additionally, real-time monitoring and automation are integrated to enhance decision-making in water use, ensuring more efficient and sustainable water management.

Applied technologies

Best practices

1. Design & Construction Best Practices

- Comprehensive Water Quality Assessment: Before system design, conduct a detailed water quality analysis to determine the optimal treatment configuration and required pre-treatment steps.

- Scalability & Flexibility: Design treatment systems with modular components (e.g., UF-RO-EDR combinations) to adapt to fluctuating water quality and process demands.

- Efficient Pre-Treatment: Implement Biologically Activated Carbon Filtration (BACF) and Ultrafiltration (UF) to reduce organic loads, suspended solids, and biofouling risks in membrane systems.

- Material Selection: Use corrosion-resistant materials for pipelines and tanks, especially in high-salinity or chemical-intensive processes.

- Redundancy & Backup Systems: Design systems with parallel treatment units or alternative pathways to ensure continuous operation in case of failures or maintenance shutdowns.

2. Operational Best Practices

-

Routine Monitoring & Data Analytics:

- Utilize real-time sensor networks to track parameters like TOC, conductivity, scaling potential, and membrane fouling indicators.

- Implement predictive analytics to anticipate failures and optimize operational efficiency.

-

Membrane System Maintenance (UF, RO, EDR):

- Schedule regular cleaning-in-place (CIP) to prevent fouling and scaling.

- Use antiscalants and biocides cautiously to extend membrane life without overuse of chemicals.

- Rotate or replace membrane modules before performance deterioration affects system efficiency.

-

Cooling Tower Water Management:

- Implement a low-chemical conditioning program to minimize blowdown waste and scaling.

- Optimize Cycles of Concentration (CoC) to reduce freshwater consumption.

-

Energy & Chemical Optimization:

- Use smart dosing strategies for coagulants and disinfectants to reduce chemical waste and costs.

- Optimize pump operation and recover energy where possible to lower operational expenses.

3. Preventive Maintenance & Risk Management

-

Scheduled Inspections & Predictive Maintenance:

- Conduct regular performance audits to detect early signs of system wear.

- Utilize machine learning-based failure prediction models to reduce unexpected downtimes.

-

Emergency & Contingency Planning:

- Maintain an inventory of critical spare parts (e.g., membranes, sensors, pumps).

- Develop a response plan for water quality fluctuations or system failures to ensure rapid recovery

Technology performance and best practices

In detail, the 3rd scenario of BACF + UF has achieved the best results:

-

Total Organic Carbon (TOC):

Feed water: ~2.0 mg/L

Permeate (post-treatment): <0.2 mg/L

(Successfully met stringent TOC requirement for boiler feed water). -

Conductivity:

Target for IEX demineralized water: <0.1 µS/cm

Achieved through consistent pretreatment enabling efficient IEX operation. -

Water Efficiency (Recovery Rate):

~97%, one of the highest among tested scenarios. -

Specific CO₂ Emissions:

0.7 kg CO₂-eq/m³ of produced demineralized water.

Lower than Scenario 1, which was 0.8 kg CO₂-eq/m³. -

Estimated Operational Cost:

1.4 €/m³ of produced water

Synergistic benefits

The application of multiple water treatment technologies at Dow Böhlen resulted in synergistic benefits, enhancing water efficiency, cost-effectiveness, and sustainability. The combination of Biologically Activated Carbon Filtration (BACF), Ultrafiltration (UF), and Reverse Osmosis (RO) provided an optimal balance of organic contaminant removal, membrane protection, and high water recovery rates. When integrated with Electrodialysis Reversal (EDR), the system improved ion removal efficiency, reducing freshwater dependency. Additionally, the smart water management system leveraged real-time monitoring and data analytics to optimize source water selection and process control, ensuring operational stability and minimizing downtime. The synergy between these technologies allowed for a more adaptive and cost-effective approach to water reuse, demonstrating how advanced treatment processes, when combined with digital monitoring tools, can significantly enhance industrial water management.

Requirements and conditions

The plant's location in a water-scarce region added constraints on resource availability, necessitating efficient treatment methods. Additionally, the variability in source water quality (from Witznitz Lake and the Elster River) required flexible treatment processes. Scaling and fouling of membranes, particularly in Reverse Osmosis (RO) and Electrodialysis Reversal (EDR) systems, posed operational challenges, requiring optimized pre-treatment (e.g., Biologically Activated Carbon Filtration (BACF) and Ultrafiltration (UF)). Cost constraints influenced technology selection, favoring lower investment and operational costs. Regulatory and environmental compliance also had to be maintained, ensuring wastewater discharge limits and industrial water quality standards were met throughout the project.

Key lessons

- Pre-treatment is essential: Effective pre-treatment using Biologically Activated Carbon Filtration (BACF) and Ultrafiltration (UF) significantly improved Reverse Osmosis (RO) and Electrodialysis Reversal (EDR) performance, reducing membrane fouling and increasing operational stability.

- Technology selection must balance cost and efficiency: While RO and EDR showed promising results for water recovery and ion removal, cost constraints and operational complexity highlighted the need for an optimal balance between investment, maintenance, and treatment effectiveness.

- Smart monitoring enhances efficiency: The integration of a real-time digital water management system improved process control, water source selection, and early detection of issues, reducing downtime and increasing adaptability to changing water quality.

- Water quality variability requires flexible solutions: The need to treat water from different sources (e.g., Witznitz Lake vs. Elster River) emphasized the importance of adjustable treatment configurations to maintain consistent water quality for industrial reuse.

- Synergistic technology combinations maximize benefits: Using multiple treatment processes together rather than relying on a single technology increased overall water savings, energy efficiency, and treatment reliability, demonstrating the value of integrated water management approaches.

Lessons learned from technology operation

-

Required Competence & Training: The operation of advanced treatment technologies like Reverse Osmosis (RO), Electrodialysis Reversal (EDR), and Biologically Activated Carbon Filtration (BACF) requires skilled personnel with expertise in membrane processes, water chemistry, and digital monitoring systems. Continuous operator training is essential to ensure optimal system performance and quick response to process variations.

-

Maintenance Challenges & Solutions:

- Membrane fouling and scaling (especially in RO and UF) were significant challenges. Regular chemical cleaning, optimized pre-treatment, and enhanced backwashing were needed to maintain efficiency.

- EDR required periodic electrode maintenance and chemical dosing to control scaling and extend membrane life.

- Sensor calibration and real-time monitoring system maintenance were crucial for accurate data-driven decisions.

-

Technological Risks & Downtime Avoidance:

- Unplanned downtime was a risk due to membrane clogging, pressure drops, or system failures. Preventive maintenance schedules and predictive analytics from the smart monitoring system helped anticipate failures and optimize cleaning cycles.

- Water quality fluctuations (e.g., from Witznitz Lake vs. Elster River) required flexible treatment configurations to maintain consistent output.

- Redundancy planning (e.g., having alternative treatment lines or backup filtration units) ensured operational continuity in case of failures.

-

Optimizing Energy & Chemical Use:

- High energy consumption in RO and EDR required careful monitoring and process optimization to reduce operational costs.

- Overuse of chemicals (e.g., antiscalants, coagulants) could lead to higher costs and environmental impact, emphasizing the need for precise dosing strategies based on real-time water quality data.

Publications and references

- Comparison of cooling tower blowdown and enhanced make up water treatment to minimize cooling water footprint

Sarah I. Müller a, Gergana Chapanova b, Thomas Diekow b, Christian Kaiser b, Lies Hamelink c, Ivaylo P. Hitsov d, Lisa Wyseure c, David H. Moed c, Laurence Palmowski a, Thomas Wintgens a,*

a Institute of Environmental Engineering (ISA) RWTH Aachen University, Mies-van-der-Rohe-Str. 1, 52072, Aachen, Germany

b Dow Olefinverbund GmbH, Olefinstraße 1, 04564, B¨ohlen, Germany

c Evides Industriewater B.V., PO box 3063 NH, Rotterdam, Netherlands

d CAPTURE (Centre for Advanced Process Technology for Urban REsource recovery), Frieda Saeysstraat 1, 9052, Gent, Belgium

https://doi.org/10.1016/j.jenvman.2024.121949

- Assessing the feasibility of using a data-driven corrosion rate model for optimizing dosages of corrosion inhibitors

Chamanthi Denisha Jayaweera 1,2,3 , David Fernandes del Pozo 1,2, Ivaylo Plamenov Hitsov 1,2,3, Maxime Van Haeverbeke 4, Thomas Diekow 5, Arne Verliefde 1,3 & Ingmar Nopens 1,2

https://doi.org/10.1038/s41529-024-00545-8

- Evaluation of various pretreatments of surface water for ion exchange demineralization in industrial applications

Sarah I. Mueller a, Eduard de las Heras García b, Lies Hamelink c, Lisa Wyseure c, David H. Moed c, Ivaylo P. Hitsov d,e, Gergana Chapanova b, Thomas Diekow b, Christian Kaiser b, Laurence Palmowski a, Thomas Wintgens a,*

a Institute of Environmental Engineering (ISA), RWTH Aachen University, Mies-van-der-Rohe-Str. 1, 52074 Aachen, Germany

b Dow Olefinverbund GmbH, Olefinstraße 1, 04564 B¨ohlen, Germany

c Evides Industriewater B.V., PO box 3063 NH, Rotterdam, Netherlands

d CAPTURE (Centre for Advanced Process Technology for Urban REsource recovery), Frieda Saeysstraat 1, 9052 Gent, Belgium

e PaInT (Particle and Interfacial Technology Group), Department of Green Chemistry and Technology, Faculty of Bioscience Engineering, Ghent University, Coupure Links 653, 9000 Ghent, Belgium

https://doi.org/10.1016/j.jwpe.2025.107224

- Evaluation of various pretreatments of surface water for ion exchange demineralization in industrial applications

Sarah I. Mueller a, Eduard de las Heras García b, Lies Hamelink c, Lisa Wyseure c, David H. Moed c, Ivaylo P. Hitsov d,e, Gergana Chapanova b, Thomas Diekow b, Christian Kaiser b, Laurence Palmowski a, Thomas Wintgens a,*

a Institute of Environmental Engineering (ISA), RWTH Aachen University, Mies-van-der-Rohe-Str. 1, 52074 Aachen, Germany

b Dow Olefinverbund GmbH, Olefinstraße 1, 04564 B¨ohlen, Germany

c Evides Industriewater B.V., PO box 3063 NH, Rotterdam, Netherlands

d CAPTURE (Centre for Advanced Process Technology for Urban REsource recovery), Frieda Saeysstraat 1, 9052 Gent, Belgium

e PaInT (Particle and Interfacial Technology Group), Department of Green Chemistry and Technology, Faculty of Bioscience Engineering, Ghent University, Coupure Links 653, 9000 Ghent, Belgium

https://doi.org/10.1016/j.jwpe.2025.107224

- Hybrid model development emulating linear polarization resistance method towards optimizing dosages of corrosion inhibitors

Chamanthi Denisha Jayaweera 1,2,4, Ivaylo Hitsov 1,2,4, David Fernandes del Pozo 1,4, Elias De Ketelaere 3, Tom Depover 3, Sarah Isabell Müller 5, Thomas Diekow 6, Arne Verliefde 2,4, Ingmar Nopens 1,4

1 –BIOMATH, Dept. of data analysis and mathematical modeling, Ghent University, Belgium

2 – PaInT, Dept. of Green chemistry and technology, Ghent university, Belgium

3 – Department of Materials, Textiles and Chemical Engineering, Ghent University, Belgium

4 – CAPTURE - Centre for Advanced Process Technology for Urban Resource recovery, Ghent, Belgium

5 – Institute of environmental engineering, RWTH Aachen University

6 – Dow Olefinverbund GmbH. Werk Böhlen Olefinstraße 1 04564 Böhlen Germany

https://doi.org/10.1016/j.electacta.2025.146116