Unique selling points

- Reduction of clean water consumption

- Low energy consumption

- Low investment and operational costs

- Flexible design: Compact and modular, meaning it can be expanded and scaled to the desired size and outflow parameters

- Unique Look & Feel:

- Botanical garden

- Architectural variability (vertical or horizontal configuration)

- Geographic flexibility (any urban environment)

- Optional space for community, education, research, or eco-tourism

Innovative plant root enhanced fixed-bed bioreactor for resource recovery

Capacity

Max capacity: 420 m3/day

Average capacity: 360 m3/day

Description of the technology

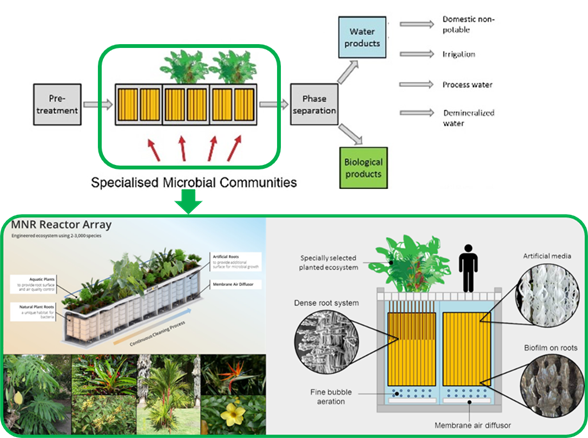

The Metabolic Network Reactor (MNR) technology is Biopolus’ patented 3rd generation Integrated Fixed-film Activated Sludge (IFAS) water treatment technology. The underlying principle behind the MNR technology is a well-known natural phenomenon, where microbial biofilm develops on the roots of aquatic plants. The technology is characterized by a large quantity of biomass that is attached to submerged „carriers” – either to the natural root system of specially selected plants, or to artificial roots, developed by Biopolus, for this specific purpose.

The full treatment process takes place in an array of MNR reactors (Flow scheme of the technology). This separation makes it possible to fine-tune the environmental conditions in each section, allowing for the development of separate, specialized ecologies to mature in the different tanks. As the water flows from reactor to reactor, it is continually cleaned, as various species break down the different contaminants. The path and volumetric distribution of wastewater between the reactors is controlled by process management software and can dynamically adapt to the changing loads, thereby optimizing the process.

While it is not the plants themselves that clean the water, they do however serve a crucial role in the engineered ecosystem of MNR technology. Specially selected plants are installed into a series of bioreactors, where the roots of the plant are submerged into the water. The fine root strands of the plants provide an ideal surface for microbial attachment. These roots are supplemented with artificial root structures, creating a large surface area for a healthy and diverse microbial community.

Typically, aquatic plants are chosen for their root structure and their ability to live in wet environments. Plants types can vary greatly, ranging from exotic tropical varieties to local native plants. Both the functionality and the aesthetic value of the plant is taken into consideration during garden design. Additional considerations include the local climate of the facility and the needs / budgetary restrictions of the client. The following figure illustrates some of the various types of plants that can be installed.

Flow scheme of the technology

MNR flow diagram and details of MNR artificial media, dense root system, and biofilm on roots

Synergetic effects and motivation for the implementation of the technology

- Reduction of wastewater volume and clean water consumption

The MNR technology can be applied in industrial sectors with an interest in reusing water. One example of this application is beer production. The produced water from the MNR can be used for bottle washing and ultimately make up water for beer production. In addition, the process returns treated water into the beer production process, minimising the volume of wastewater as well as reducing clean water consumption during the beer production up to 80%.

- Solution as a circular urban water network

Conventional wastewater treatment facilities can be transformed or replaced by modular, compact, and odour-free MNR technology. Specifically, the utilization of MNR technology can free up some space for redevelopment and give us an opportunity to build green urban infrastructure. Therefore, the MNR technology can be fully integrated into the urban environment, providing a platform for a sustainable urban water cycle.

Technology requirements and operating conditions

The following tables summarize the general parameters of the MNR process at the LaTrapp facility. Due to operational delays related to Covid19, the NextGen project will now focus on the industrial wastewater treatment line; therefore the parameters listed below are for the industrial wastewater treatment line.

General data

|

Parameter |

Units |

Min |

Max |

Reference |

|

pH* |

- |

4 |

12 |

NextGen D1.3 (in prep.) |

|

Temperature |

°C |

15 |

30 |

NextGen D1.3 (in prep.) |

|

Flow Rate |

m3/day |

320 (average) |

420 (max) |

NextGen D1.3 (in prep.) |

* The influent concentrations have large fluctuations, which arise from the various processes and cleaning schedules of the brewery.

Key performance indicators

|

Parameter |

Units |

Design Influent |

Design Effluent |

Removal Efficiency (%) |

Reference |

|

COD* |

mg/L |

3,080 |

125 |

96 |

NextGen D1.3 (in prep.) |

|

BOD |

mg/L |

1,904 |

20 |

99 |

NextGen D1.3 (in prep.) |

|

NH4-N |

mgN/L |

3.0 |

1 |

33 |

NextGen D1.3 (in prep.) |

|

TN |

mgN/L |

34.5 |

10 |

71 |

NextGen D1.3 (in prep.) |

|

TP* |

mgP/L |

15.2 |

0.3 |

98 |

NextGen D1.3 (in prep.) |

|

TSS |

mg/L |

252 |

2 |

99 |

NextGen D1.3 (in prep.) |

Links to related topics and similar reference projects

|

Biological wastewater treatment technology |

Reference |

|

Case study “Athens” (NextGen) |