Unique selling points

- Compact solution for wastewater treatment and reclamation compared to conventional biological sludge treatment.

- Regenerated water with high quality which can be reused for irrigation or other non-potable uses.

Description of the technology

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment one, the activated sludge process. It is now widely used for municipal and industrial wastewater treatments. Two MBR configurations exist: internal/submerged, where the membranes are immersed an integrated into the biological reactor; and external/sidestream, where membranes are a separate unit process requiring an intermediate pumping step.

MBR are frequently used to reduce treatment footprint while obtaining high water quality that can be reused.

In the NextGen project, the MBR treatment will be applied for sewer water mining, treating water directly extracted from sewer and producing water to be reused for irrigation in an urban green zone. The MBR has been tested up to industrial scale. In the Nextgen project, the tested capacity of the MBR is around 25m3/d.

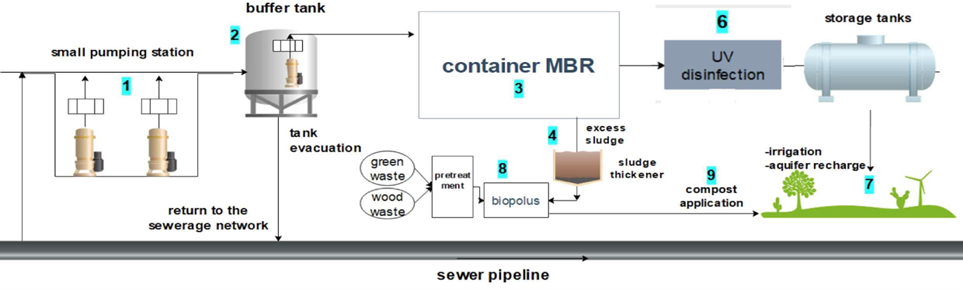

Flow scheme of the technology

Figure 1. Scheme of the NextGen pilot plant where MBR system is applied.

Figure 1. Scheme of the NextGen pilot plant where MBR system is applied.

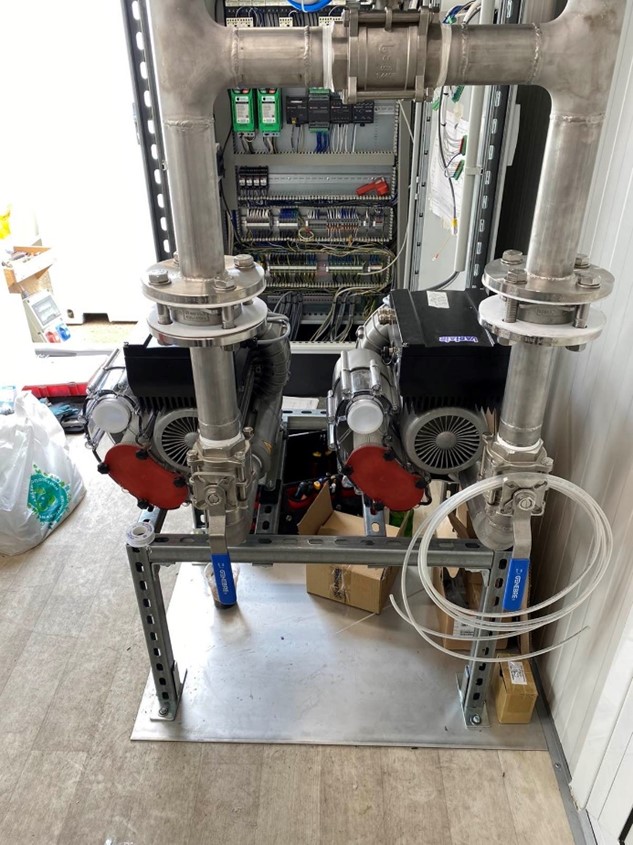

Pictures

Synergetic effects and motivation for the implementation of the technology

- Production of reclaimed water from sewer in the point of use

MBR with desired sizes can be installed in decentralized systems to treat sewer extracted from the collector. Reclaimed water with high quality can be produced in the point of use, minimizing the costs of distribution.

Technology requirements and operating conditions

The following table summarize the most appropriated values of several parameters to take into account for the design and operation of an MBR.

Table 1. Required specifications for an MBR.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Organic Loading Rate (OLR) |

Kg/m3/d |

0.1 |

13 |

Depending on the wastewater type (urban or industrial). |

|

Sludge concentration (Volatile Suspended solids) |

g/L |

4 |

12 |

|

|

Mixed liquor suspended solids (MLSS) or Total Suspended Solids |

g/L |

8 |

12 |

Delgado, et al., 2011 |

|

Solid retention time (SRT) |

d |

10 |

20 |

Delgado, et al., 2011 |

|

Specific aeration demand SADm |

Nm3/h m2 |

0.30 |

0.57 |

Delgado, et al., 2011 |

|

Membrane porous size |

nm |

10 |

400 |

Delgado, et al., 2011 |

|

Gap sizes for the screens used during the pre-treatment |

mm |

0.5 |

3 |

|

|

Operation flux rates |

LMH |

14 |

48 |

Key performance indicators

Table 2. KPIs for the MBR in the Athens case study provided in NextGen, D1.2.

|

Parameter |

Units |

Min |

Max |

Legislation Limits |

|

COD concentration in the MBR effluent |

mg O2/L |

13 |

32 |

- |

|

BOD concentration in the MBR effluent |

mg O2/L |

1 |

2.5 |

≤10 ppm for 80% of samples |

|

TSS concentration in the MBR effluent |

mg/L |

Detection Limit |

Detection Limit (2) |

≤2 ppm for 80% of samples |

|

Turbidity in the MBR effluent |

NTU |

0.1 |

2.0 |

|

|

N-NH4+ concentration in the MBR effluent |

mg/L |

60 |

85 |

|

|

Total P concentration in the MBR effluent |

ppm |

5.0 |

7.0 |

|

|

Energy consumption |

KW |

15 |

17 |

|

|

Volume of sludge generated |

L |

700 |

1000 |

|

Links to related topics and similar reference projects

|

MBR treatment |

Reference |

|

NextGen |

Case Studies applying the technology

Publications

- Boonyungyuen, W., Wonglertarak, W. Wichitsathian, B., Effect of Organic Loading Rate on the Performance of a Membrane Bioreactor (MBR) Treating Textile Wastewater, 2014

- Delgado, S. Villaroel, R., González, E. and Morales, M., Performance Under Substrate-Limited Conditions, 2011

- Holler, S. and Trösch, W., Treatment of urban wastewater in a membrane bioreactor at high organic loading rates, 2001

- Plana Puig, Q., Nanu, C., Groza, I., Soares, A., Vale, P., Monokrousou, K., Makropoulos, C., Katsouras, G., Tsalas, N., Tazes, N., Tsimnadis, K., Lindeboom, R., Plata, C., Suters, R., Kenyeres, I., Plà, M., Filipsson, S., Hedman, F., Kim, J., Hofman, J.,, D1.3 New approaches and best practices for closing the water cycle, 2022

- Schier, W. Frechen, F.B., Fischer, St., Efficiency of mechanical pre-treatment on European MBR plants, 2009

- Yang, Q., Shang, H. T. and Wang, J. L., Treatment of municipal wastewater by membrane bioreactor: a pilot study, 2009