Unique selling points

- High removal percentages related to the influent for emerging/priority substances and organic degradation by-products (nearly 100%), metals and high elimination of oxidant species.

- Cost-effective posttreatment.

Description of the technology

Activated carbon is frequently used as a posttreatment process to refine water quality, i.e., to diminish the quantity of different types of organic compounds such as certain degradation by-products generated in the previous Advanced Oxidation Process (AOP) (such as hydrogen peroxide photolysis, ozonation, UV/ozonation, etc.). It is based on the adsorption of several chemical species on its surface or on its low-volume porous.

Activated carbon is usually derived from charcoal. When granulated, it is called granulated activated carbon (GAC). Recently, different types of activated carbons have been prepared from dried sewage sludge using CO2, air, alkali metal hydroxides, etc. as activating agents (Monsalvo, et al., 2011). They are characterized by its high surface area, pore size distribution, absorptive and catalytic properties, all of them depending on the raw materials and manufacturing processes that produce them (National Research Council (US) Safe Drinking Water Committee, 1980).

In the Nextgen project, activated carbon will be used as single treatment to remove some specific organic trace compounds but also coupled after an UV/H2O2, ozonation or UV/O3 systems.

The capacity of NextGen’s pilot is 0.75 – 3.0 m3/h.

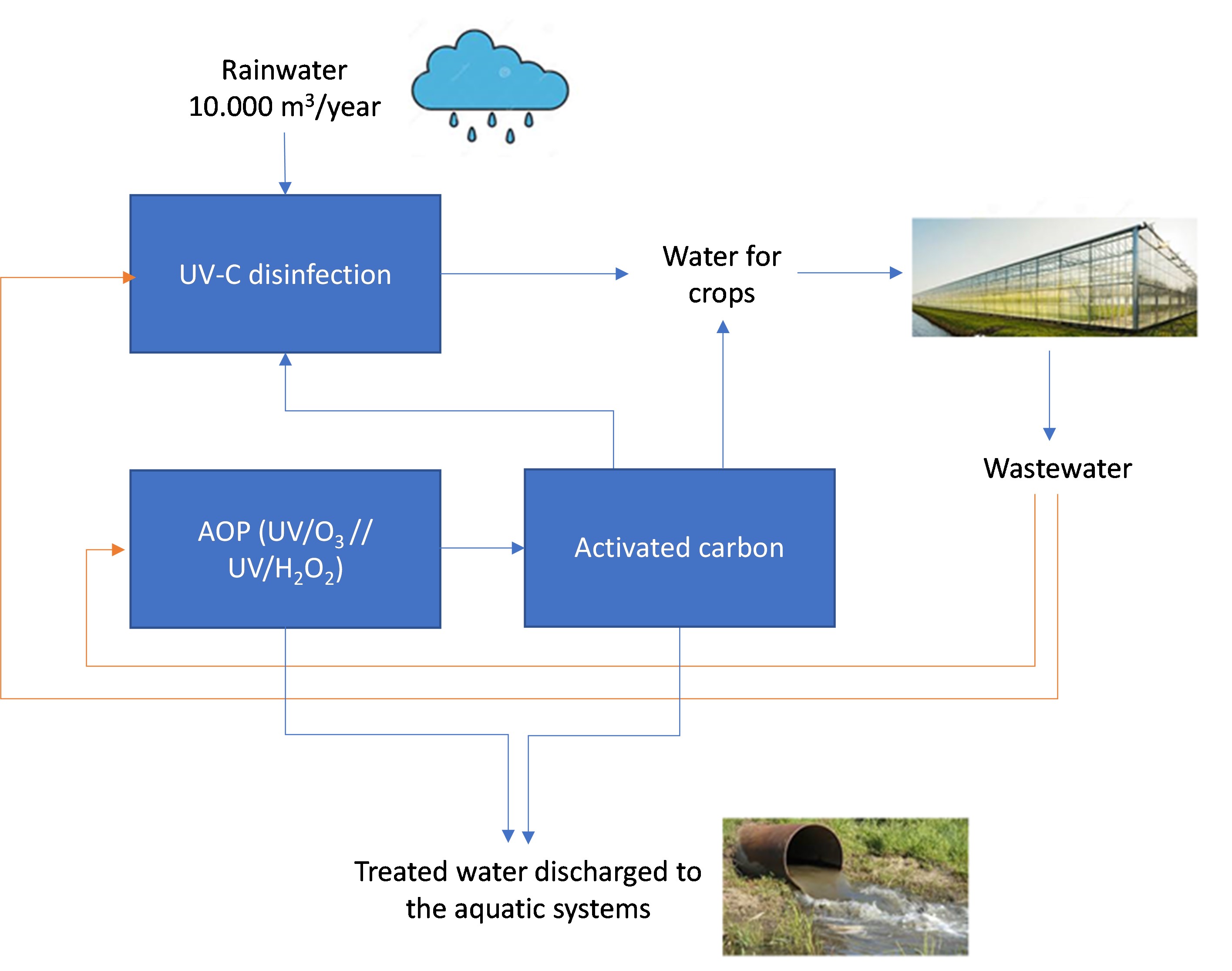

Flow scheme of the technology

Simplified diagram of one of the NextGen strategies where the activated carbon process coupled to an AOP is being applied (Westland region).

Figure 1. Simplified diagram of one of the NextGen strategies.

Pictures

Synergetic effects and motivation for the implementation of the technology

- Reduction of the organic metabolites that reach aquatic systems.

The impact to the environment due to the release of certain degradation by-products, which can present higher toxicity than the original pollutants, can be minimized by removing them by coupling the activated carbon to an AOP such as the UV/H2O2 or UV/O3 processes. Therefore, preventing certain effects on the fauna related to endocrine disrupting process as well as protecting the flora.

- Reduction of the drinking water consumption destined to irrigation.

Activated carbon coupled to H2O2/UV or O3/UV processes will remove the degradation metabolites from the original organic pollutants as well as it will reduce the content of oxidant species. Therefore, this treatment train produce regenerated water to be used for irrigation purposed in the greenhouses (focused on zero PPPS discharge legislation of Netherlands). This will contribute to reduce the quantity of drinking water consumed for this application, therefore improving the availability of this resource.

- Establishment of a circular economy concept (by using an activated carbon from sewage sludge).

The valorisation of sewage sludge through its conversion to an activated carbon with enough capacity to remove certain trace organic compounds as well as several oxidant species is demonstrated during the NextGen project. The activated carbon coming from the pre-treated sewage sludge is a cost-effective material that can be applied after an AOP to obtain regenerated water with desired quality to be reused.

Therefore, this practice increases the circularity in the water process.

Technology requirements and operating conditions

The activated carbon can be used as a ‘stand alone’ process or as refinement technology after the oxidation treatment. The following table summarize the most appropriated values of several parameters to be considered during the operation of activated carbon technology.

Table 1. Required specifications for the activated carbon process.

|

Parameter |

Units |

Min |

Max |

Reference |

|

DOC |

mg/L |

1 |

10 |

|

|

Empty bed contact time (EBCT)* |

min |

5 |

120 |

|

|

Upflow Velocity |

m/h |

5 |

15 |

|

|

Bed Volumes (BV)** |

[-] |

1,000 |

50,000 |

Reungoat et al., 2010 |

|

Backwash |

% of incoming flow |

5 |

20 |

Mulder et al., 2015 |

|

GAC replacement |

|

After 7000 BV |

Before 15,000 BV |

Mulder et al., 2015 |

*EBCT = [[Carbon Volume (m3)*60(min/h)]/Flowrate (m3/h)]

** BV = [m3water/m3GAC]

Key performance indicators

As commented before, the activated carbon treatment is mainly focused in reducing the organic as well as the turbidity contents. Therefore, these will be one of the main KPIs to be monitored, together with the empty bed contact time (EBCT).

Table 2. KPIs for the activated carbon process.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Global removal yield of organic matter |

Total organic content (TOC) removed (%) |

20 |

99 |

|

|

Global removal yield of turbidity |

Turbidity removed (%) |

25 |

95 |

Hatt et al., 2013 |

|

EBCT |

min |

5 |

120 |

Links to related topics and similar reference projects

|

Activated carbon treatment |

Reference |

|

NextGen – GAC treatment |

|

|

NextGen – GAC production |

Case Study applying the technology

Publications

- Cuerda-Correa, E., Alexandre-Franco, M. F and Fernández-González, C., Advanced Oxidation Processes for the Removal of Antibiotics from Water. An Overview., 2020

- Hatt, J.W., Germain, E., Judd, S. J., Granular activated carbon for removal of organic matter and turbidity from secondary wastewater, 2013

- Meinel, F., Ruhl, A. S., Sperlich, A., Zietzschmann, F. and Jekel, M., Pilot-Scale Investigation of Micropollutant Removal with Granular and Powdered Activated Carbon., 2015

- Monsalvo, V.M., Fernandez Mohedano, A., Rodriguez, J.J., Activated carbons from sewage sludge: Application to aqueous-phase adsorption of 4-chlorophenol., 2011

- Mulder, M., Antakyali, D., and Ante, S., Verwijdering van microverontreinigingen uit effluenten van RWZI’s (Costs of Removal of Micropollutants from Effluents of Municipal Wastewater Treatment Plants)., 2015

- National Research Council (US) Safe Drinking Water Committee, An Evaluation of Activated Carbon for Drinking Water Treatment. In: Drinking Water and Health: Volume 2, 1980

- Reungoat, J., Macova, M., Escher, B. I., Carswell, S., Mueller, J. F., and Keller, J., Removal of micropollutants and reduction of biological activity in a full scale reclamation plant using ozonation and activated carbon filtration., 2010