Unique selling points

- Green Technology

- Water as an extraction solvent has the advantage of being green, cheap, and readily available

- Polar, moderately polar, low-polar and non-polar compounds can be extracted separately

- No use of organic solvents

- No residual organic solvents in the extract

- Less expensive instrumentation

- Faster Extraction Time

- Continuous operation is possible

Subcritical water extraction (SWE) is a promising engineering method, which provides an environmentally friendly technology for extracting various bioactive compounds from natural products. Especially, under high temperature and high pressure, subcritical water can change the polarity and dielectric constant of solvents, thus contributing to a better extraction process, improving the mass transfer efficiency of the extracts and maintaining its biological activities, which has a high application prospect (Zhang et al., 2020).

Description of the technology

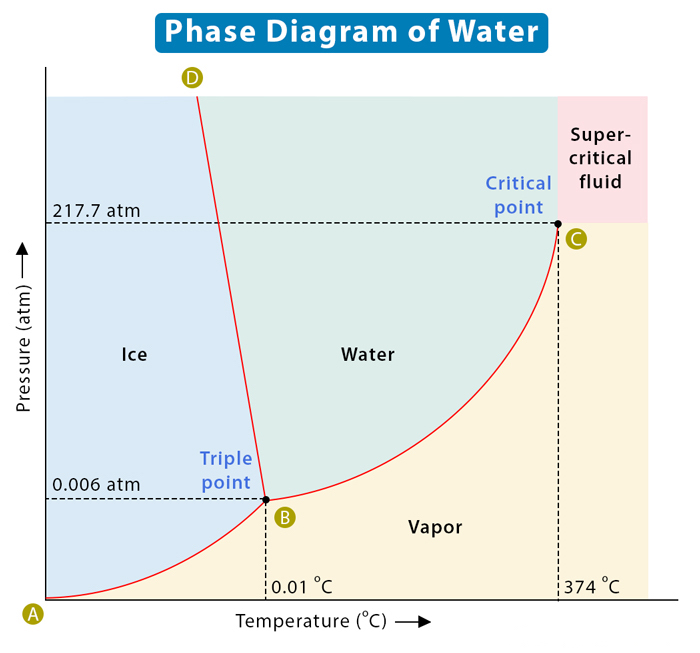

Subcritical Water Extraction (SWE) is a method that benefits from the solvent properties of subcritical water. i.e. water at temperatures above the boiling point i.e., elevated pressures in order to keep it in liquid state, as seen in the phase diagram below Figure 1, with a working range between 100-250°C and 100-200 bar.

The subcritical water extraction can also be applied directly on undried matrices.

Figure 1 Phase diagram of water.

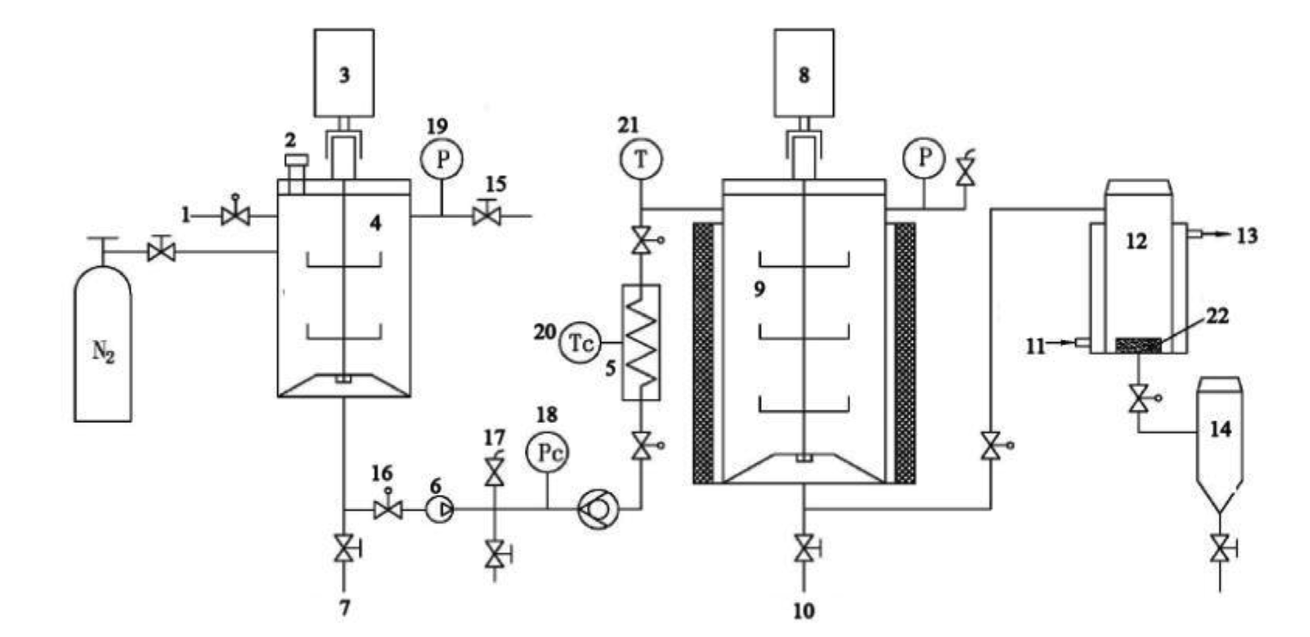

Figure 2 Schematic diagram of SWE system. (1) water inlet; (2) feed inlet; (3) stirring system; (4) solid samples extraction cell; (5) heat exchanger; (6) pressure pump; (7) impounding reservoir; (8) stirring system; (9) solid samples extraction cell; (10) impounding reservoir; (11) cooling water inlet; (12) cooling pan; (13) cooling water outlet; (14) collector; (15) globe valve; (16) spherical valve; (17) safety valve; (18) pressure regulator controller; (19) pressure indicator; (20) temperature regulator controller; (21) temperature indicator; (22) filter plate (Zhang et al., 2020).

Subcritical water extraction follows the same principles of the liquid extraction but the pressurized conditions diversify the properties of the water as a solvent (Castro-Puyana et al., 2013).

Figure 4 Picture of the Subcritical Water Extractor

Figure 4 Simple static equipment of SWE in laboratory (A); industrial dynamic equipment of SWE (B, C) (Zhang et al., 2020).

Flow scheme of the technology

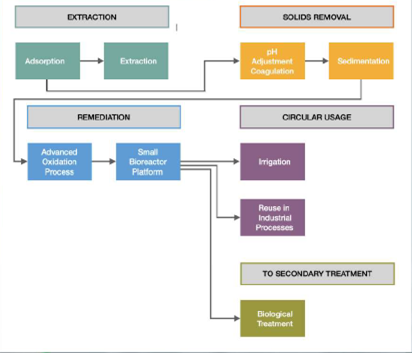

In the framework of the ULTIMATE project, in the Work Package 1, Subcritical Water Extraction is applied to extract antioxidants (polyphenols) from fruit processing water by-product. The industrial by-product flows through a macroreticular, non-fuctionalised adsorbent resin where the polyphenols are adsorbed. These polyphenols are recovered by subcritical water extraction.

Figure 3 Flow diagram of the process

Synergetic effects and motivation for the implementation of the technology

- Green Technology

Subcritical Water Extraction reduces or even eliminates the use of organic solvents thus it be categorized as a green environmentally friendly method.

- Quality of the extract

A major advantage of the elimination of organic solvents is that the final product/extract is free of organic residues thus it is of higher quality and safer for consumption.

Technology requirements and operating conditions

Tab. 1 Operational requirements for Subcritical Water Extraction operation

|

Parameter |

Value |

Reference |

|

Water temperature |

100-374ºC |

|

|

Water pressure |

1-22.1 MPa |

|

|

Extraction time |

2-120 min |

|

|

Solvent flow rate |

4mL/min |

Key performance indicators

Tab. 2 Key parameters for Subcritical Water Extraction operation

|

Parameter |

Unit |

|

Extraction efficiency (yield) |

(Amount extracted/total amount in raw material)*100% |

|

Solvent consumption |

L water consumed/kg raw material |

|

Energy consumption |

kWh energy consumed/ kg raw material |

|

Product purity |

(Mass of target compound in extract/Total mass of extract)*100% |

Links to related topics and similar reference projects

|

Process/technologies |

Reference |

|

Antioxidants from winery waste |

|

|

Extraction of polyphenols from lotus seed pop |

|

|

Olive polyphenols extraction |